Abstract

Aim:

The unfermented pale-yellow exudates (“palm sap”) emerge from tapped unopened spathe of mostly oil palm (Elaeis guineensis) and raphia palm (Raphia hookeri). Besides, tiger nut milk (Kunuaya) is among the non-alcoholic refreshing drinks with dairy appearance. A sustainable alternative could therefore emerge from blends of tiger nut milk and sugar syrup to serve a resembling role as palm wine. In this context, therefore, palm wine analogue from different tiger nut milk and sugar syrup blends using palm wine dreg as inoculum was evaluated by proximate, physicochemical, microbial, and sensorial analyses at different time intervals.

Methods:

The materials were processed, analyzed, and packed using standard referenced procedures. This required freshly tapped palm sap juxtaposed with blends of tiger nut milk-sugar syrup beverage, and thereafter subjected to aerobic fermentation. Importantly, the tiger nut milk-sugar syrup medium has been pitched with palm wine dreg (inoculum source) between fermentation time 26–30 h, and temperature 29.8°–32°C.

Results:

Considering all the analytical outcomes, from proximate, microbiological, physicochemical, to sensory data, the control appeared to somewhat resemble those of the experimental samples of this study.

Conclusions:

Potentially, the (palm wine) analogue produced from tiger nut milk and sugar syrup blends using (palm wine) dreg as inoculum could be embraced by the market as natural palm wine. Indeed, the emergent product should serve as an alternative sustainable promise for palm wine, which could help fill the market supply gap, especially in the seasons of reduced supply/yield.

Keywords

Dreg, food security, palm wine, product development, sugar syrup, tiger nut milkIntroduction

Palm trees are among common plant species useful in mixed farming systems given their subsistence and commercial end-use. In particular, there is the unfermented pale yellow exudates from tapped unopened spathe of mostly oil palm (Elaeis guineensis) and raphia palm (Raphia hookeri) called the palm sap, which is among the multiple (palm tree) products in many tropical countries [1]. Fermented palm sap, usually called palm toddy/palm wine represents a whitish, effervescent, alcoholic beverage produced by spontaneous fermentation. In tropical and subtropical countries such as South America, Asia, and Africa where palm trees thrive, the (palm) wine emergent from the sap remains a refreshing alcoholic beverage [2]. In particular, there is a heavy suspension of yeasts and bacteria in fermenting palm sap in palm wine [3]. Across localities and nations, palm wine is called by different names, like Palmy, Mmayangwo, Nkwuelu, Mmanyaocha, Emu, Oguro in Nigeria; Matango, Mbuh, Tumbu liquor, white stuff in Cameroon; Poyo in Sierra leone; Nsamba in the Democratic Republic of the Congo; Manjenvo in Cabinda Angola; Nsafufo in Ghana, among other. Specific to the southeastern part of Nigeria, the dreg of palm wine is reserved to boost the sexual performance and fertility of newly wedded men, although there is a dearth of scientific evidence to prove these claims [2].

Tiger nut milk (Kunuaya), a non-alcoholic refreshing drink of dairy appearance, comprises promising energy content (starch, fat, sugar, and protein), minerals (mainly phosphorus and potassium), and vitamins E and C [4]. Considered a wholesome food able to produce nut milk, the tiger nut has attracted increasing scientific research, not only because of its use for making beverages, gluten-free bread, milk, and snacks but also its functional properties, which when modified, make them suitable for industrial production [5]. Despite the presence of ample starch in tiger nut, earlier reports show it appears not yet thriving commercially/industrially, especially in the West African sub-regio. Moreover, if there is no sugar (and yeast), there would be no wine, as the yeast converts sugars through enzymatic actions, to produce CO2 and alcohol [6]. More so, the development of new products from the tubers of tiger nuts could contribute to enhancing the interest in this “underground walnut” [5]. Moreover, sucrose—a sweet unfermented sap can be considered a colorless syrup containing 10–12% sugar. The inherent fermentation-based microbial process helps to turn the milky-white palm sap into (palm) wine. The fermentation rate of palm sap to palm wine varies with storage conditions and time. The fermentative ability of microorganisms poses difficulty in palm sap to retain its normal characteristics during storage [7].

Given the sugary nature of the sap, however, the onset of microbial proliferation could become inevitable/persistent. A contaminated sap would, therefore, emerge as a viable nutrient medium for microbial (bacteria and yeast) proliferation. Post-invasion of microbial entities, the fermentation of sap begins which if left unchecked would convert to sugar, then to alcohol/organic acids, and eventually, aldehydes, esters, and other associated chemical compounds, all of which are believed to help preserve the wine [6–8]. Nonetheless, assuming there existed a categorized level of scarcity in the availability of palm wine, could an alternative be made available even from the blends of tiger nut milk and sugar syrup to serve the same purpose as palm wine? The individual/group consideration of sugar syrup/tiger nut milk may serve as raw materials for alcohol in wine production as both contain fermentable sugars. To supplement existing information, therefore, this current work evaluated palm wine analogue from different tiger nut milk and sugar syrup blends using palm wine dreg as an inoculum. The overall target was to develop a pathway that can help maximize the utilization, processing, as well as preservation of tiger nuts along with palm wine in such a sustainable manner that helps to promote food security.

Materials and methods

All laboratory procedures, from the collection of raw materials to the analytical measurements were conducted in accordance with the relevant laboratory guidelines as prescribed by the Department of Food Science and Technology, Department of Nutrition and Dietetics, as well as the Energy Centre, all situated at the University of Nigeria, Nsukka, Enugu State, Nigeria.

Raw materials

The principal raw materials were palm sap/palm wine, sugar (fermentable), and tiger nuts. The palm sap/palm wine was procured from palm wine tapper from Owerre Enugu-Ezike in Igbo-Eze local government area of Enugu State-Nigeria, and placed in a cooler packed with ice blocks. The fermentable sugar was procured from Ogige market, Nsukka, Enugu State, whereas the tiger nut was procured from the main market, Taraba State, Nigeria. The materials were processed, analyzed, and packed at the Department of Food Science and Technology, Department of Nutrition and Dietetics, as well as Energy Centre, University of Nigeria, Nsukka, Enugu State, Nigeria.

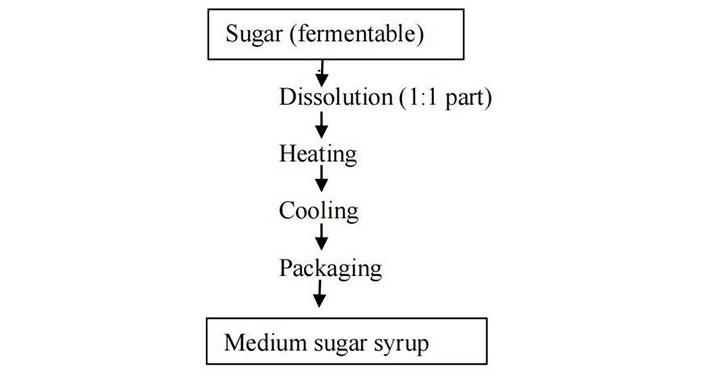

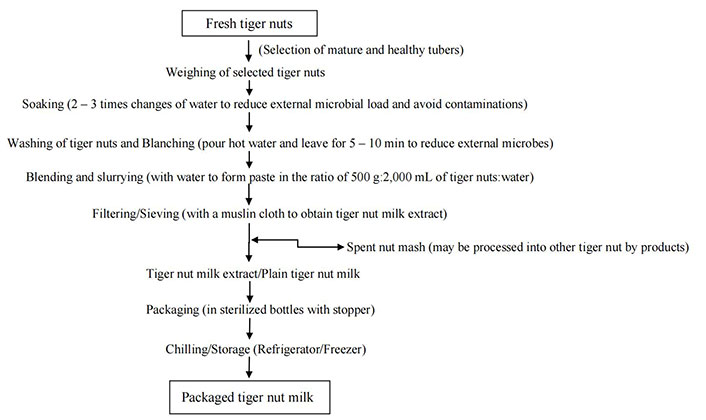

Preparation of sugar syrup, and tiger nut milk

The production of sugar syrup is presented in Figure 1, as modified by Mudoga et al. [9]. In a high-sided saucepan over medium-high heat, cold water and sugar were brought to a boil. The heat was turned low, and the mixture was stirred constantly until the sugar dissolved completely and became clear (that is, no sugar crystal was detectable), for approximately 3 min to 5 min. After boiling, the syrup was cooled and then poured into a sealable clean glass jar (or any other container) and stored in the refrigerator [9]. The flow diagram for the production of tiger nut milky beverage is shown in Figure 2. The tiger nut milk preparation was soaked and subsequently washed, blanched, and blended, which subsequently formed the slurry. Filtration and sieving enabled the milk extract to be formed, thereafter packaging and refrigerated storage [10].

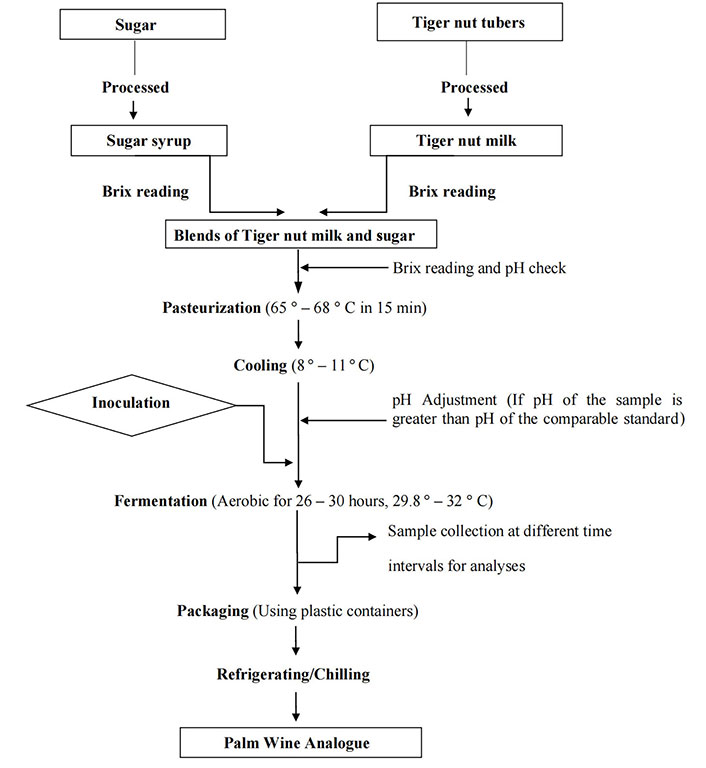

Pre-fermentation preparations, fermentation, and blending of raw materials

A quantized drop of raw materials was collected, with sucrose in the solution ascertained by degrees Brix (oBrix) by refractometer, according to fruit-type acid content [11]. The nubs/spindles were adjusted with the scores recorded from the displaying screen of the device, thereafter readings were tabulated in Table 1. The production of palm wine analogue from tiger nut milk and sugar blends is shown in Figure 3, where palm wine drew has specifically served as inoculum. After degrees, Brix readings of 6.44 and 57.45 were respectively compared, and the blending of the tiger nut milk and sugar syrup, fermentation was implemented, to achieve an alcohol content of 5–8% [12, 13]. Once some proportions of the sugar syrup were poured into the tiger nut milk, the mixture was stirred very well with a wooden stirrer, and the needed droplet was collected and subjected to degrees Brix reading (Figure 3). The process first aimed to attain the degrees Brix of palm sap (13.50) as a comparison standard and continued until it reached the value of 14.12. This value was viewed as acceptable considering that no amount of fermentation activities was present in the tiger nut milk-sugar syrup beverage prior to the setup and start of the experimental process that may reduce the degrees Brix to 13.50 as in the palm sap. During the blending of the tiger nut milk with sugar syrup, a total of 2,000 mL of sugar syrup was added to 2,500 mL of tiger nut milk to achieve a blend that had degrees Brix reading of 14.12.

Degrees Brix readings of the raw materials

| No. | Materials | Degrees Brix (oBrix) |

|---|---|---|

| 1 | Palm wine dreg | 3.19 |

| 2 | Palm sap | 13.50 |

| 3 | Tiger nut milk | 6.44 |

| 4 | Sugar syrup | 57.45 |

| 5 | Blends of 3 and 4 | 14.12 |

The production of palm wine analogue from tiger nut milk and sugar blends using an inoculum (palm wine dreg)

Media preparations, pasteurization, and pre-fermentation activity

Media placements

The tiger nut milk-sugar syrup beverage and the palm sap were placed into two different fermentation vats of 2,500 mL and 1,480 mL, respectively. Each of the two fermentation vats was equipped with a bucket (15 liters), valve, thermometer, and a pipe connected for aerobic fermentation. The inoculum was standardized by determining the cell density as well as types so as to ensure consistent inoculation of the fermenter. Importantly, there was the use of an aseptic technique throughout the preparation process of the fermentation process in order to prevent any form of contamination. Specifically, there was aseptic handling of the inoculation process with the standardized inoculum, especially the mixing of the inoculum with the fermentation medium to ensure even growth and product formation. In addition, the valve assists in collecting samples at various intervals after the swirling/shaking of the vat. The thermometer helps to detect the temperature of the surrounding medium.

Pasteurization, pH check/adjustment, and mother culture preparation

The essence of pasteurization was to kill existing pathogenic and non-pathogenic microorganisms, and thus make way for only the target/chosen microorganism(s) to carry on with the fermentation process. Each of the two fermentation containers had its content exposed to heat treatment of 65°–68°C for 15 min. Heat spread or convection was facilitated by a wooden stirrer which was applied at various intervals. Upon the completion of pasteurization, the pot was removed from the heat source, poured back into the fermenting containers, and allowed to cool to 8°–11°C, aerated to saturation, and then tightly covered. The fermenting containers were then labeled as A for palm sap and E for tiger nut milk-sugar syrup beverage.

The pH of pasteurized tiger nut milk-sugar syrup beverage read 4.6, whereas that of palm sap (comparable standard) was 4.0. Based on these values, the pH of tiger nut milk-sugar syrup beverage needed further adjustment. Also, 0.1 N of NH4Cl (food grade) helped to adjust the pH from 4.6 to 4.0. The sum of 0.585 g of NH4Cl was dissolved in water and made up to 100 mL. The solution was poured slowly at a time, the fermentation vat stirred, and the pH was checked until the target (pH) was reached.

Five hundred (500) mL of cooling wort/beverage was poured into an air-tight container, and upon cooling to a temperature (70°F/21°C) that would not harm fermenting microorganisms, 50 mL of palm wine dregs were placed in an air-tight container at a sterile environment, and thereafter tightly covered. After 6 h, the mother culture was proportionately transferred into the fermentation medium, still in a sterile environment. Subsequently, the pre-fermentation samples were collected and subjected to the various analytical measurements.

Fermentation process and analytical labels

The fermenting media were kept inside the fermentation room of the Department of Food Science and Technology, University of Nigeria Nsukka fermentation temperature of 27°C to 38°C. Agitation of the fermenting vats was done at intervals of time in order to maintain a homogenous culture. The water that collects the carbon (IV) oxides from the aerobic fermentation vats was also changed periodically to avoid a throwback and cross-contamination. The temperature of the media fluctuated between the ranges of 29.8°–32°C. Samples for analyses were collected in certain designed categories of time intervals throughout the fermentation period of 26–30 h (0th h, 2nd h, 5th h, 9th h, 14th h, 20th h, and 26th h).

The fermentation medium that contained the palm wine analogue (primordial beverage—the blend of tiger nut milk and sugar syrup) was labeled E whereas the other fermentation medium that contained the experimental palm sap was labeled A. The experimental palm sap was the freshly tapped palm sap from four different palm trees of the same species (Elias guinensis) that were analyzed alongside the content of the medium, E. Analyses to determine the proximate composition, physicochemical properties, alcoholic volume, microbial, and sensory evaluation of the various contents of the fermentation media, A and E, were conducted at varied time intervals of 2 h, 3 h, 4 h, 5 h, and 6 h, and another 6 h, summing up to 26 h of fermentation exposure. Sample AEC was set as the control in this phase of analyses. Thus, the hourly interval analyses were arranged to take the form of 0th, 2nd, 5th, 9th, 14th, 20th, and 26th making them seven levels/categories of analyses.

Analytical measurements

Physicochemical and micronutrient analyses

Proximate composition was determined for moisture content, crude protein, crude fiber, crude fat, crude ash, and carbohydrate contents using the standard methods of AOAC [14]. Moisture content was gravimetrically determined by differential weighing via hot air oven drying before and after at 105° ± 2°C for 24 h. The fat content of the sample was determined by the Soxhlet extraction method, adopting the international standard ISO-659 with hexane as solvent. Whereas the ash content of kocho was determined by using a muffle furnace, the total carbohydrate of samples was estimated by the well-established difference method. Total soluble solids (TSS), pH, titratable acidity, sugar content (Brix reading), viscosity, and alcohol contents, were determined using standard methods of AOAC [14]. Micronutrients such as vitamins A and C, zinc, iron, iodine, and calcium (before and after fermentation) were determined using the standard methods of AOAC [14].

Microbiological analyses

The microbiological analyses involved the determination of total viable count (TVC) and mold counts via the pour-plate method modified from the description given by Prescott et al. [15]. TVC involved roughly 26 g of nutrient agar (NA) dissolved in a diluent subsequently enumerated by serial dilutions, followed by incubation (37°C for 24 h). Mold count involved roughly 15 mL of saboraud dextrose agar (SDA) dissolved in a diluent subsequently enumerated by serial dilutions, followed by incubation (37°C for 24 h). In both situations, the microbiological load was represented in terms of colony-forming units (CFU) per mL.

Sensory evaluation

The sensory evaluation employed 20-panel members familiar with the quality attributes of palm wine. A 9-point Hedonic scale ranging from like extremely (9) to dislike extremely (1). Panel members were presented with samples placed in coded identical white cups. Prior to the sensory evaluation activity, the use of verbal consent was applied to panel members as per routine (departmental) activity and approved by an Internal Review Committee within the Department of Food Science and Technology, University of Nigeria Nsukka. Sensory evaluation participation was voluntary, and to ensure privacy no names/gender was reported. Each sample was rated for appearance, flavor, clarity, taste, aftertaste, mouthfeel, consistency, tartness, and overall acceptability, alongside the reference/market sample for comparison. Following the method of Çakmakçı et al. [16], each panelist took warm water to cleanse taste palates between samples, to avoid bias.

Statistical analysis

The data generated were subjected to a one-way analysis of variance (ANOVA) with a probability level set at p < 0.05 (95% confidence interval). The mean separation employed the least significant difference (LSD) test. Statistical Package for Social Science (SPSS) version 23.0 for Windows was used to run the data.

Results

Proximate comparisons

Proximate compositions of analogue and experimental palm sap samples at various time intervals are shown in Table 2. Sample assessment specific to palm wine analogue sample E5 measured at 14th h had the highest crude protein (0.069%), followed by sample E2 (0.067%), measured at 2nd h, before sample E7, measured at 26th h (0.034%). Similarly, the experimental palm wine sample A2 measured at 2nd h had crude protein of 0.063% followed by sample A5, measured at 14th h (0.060%), whereas, sample A7, measured at 26th h with the least (0.027%). Overall, both samples (A and E) fluctuated (increases and decreases) across time intervals (0th–26th h).

Proximate composition between palm wine analogue samples (E1–E7) and experimental palm sap samples (A1–A7) at various time intervals (0th–26th h)

| Time interval (hour) | Parameters samples | Crude protein (%) | Ash (%) | Crude fat (%) | Moisture (%) | Crude fiber (%) | Carbohydrate (%) |

|---|---|---|---|---|---|---|---|

| 0th | A1 | 0.058 ± 0.001ef | 0.382 ± 0.001ef | 0.00 ± 0.00a | 96.68 ± 0.007i | 0.00 ± 0.00 | 2.88 ± 0.006d |

| E1 | 0.057 ± 0.001ef | 0.383 ± 0.001efg | 4.53 ± 0.021h | 88.61 ± 0.014b | 0.10 ± 0.00 | 6.32 ± 0.007j | |

| 2nd | A2 | 0.063 ± 0.001h | 0.387 ± 0.002hi | 0.00 ± 0.00a | 96.10 ± 0.014g | 0.00 ± 0.00 | 3.45 ± 0.011f |

| E2 | 0.067 ± 0.001i | 0.493 ± 0.001j | 4.33 ± 0.014g | 87.71 ± 0.021a | 0.10 ± 0.00 | 7.40 ± 0.035l | |

| 5th | A3 | 0.056 ± 0.000e | 0.384 ± 0.002c | 0.00 ± 0.00a | 97.02 ± 0.014j | 0.00 ± 0.00 | 2.54 ± 0.012c |

| E3 | 0.062 ± 0.001gh | 0.386 ± 0.001de | 3.80 ± 0.035f | 87.772 ± 0.007a | 0.10 ± 0.00 | 7.98 ± 0.040m | |

| 9th | A4 | 0.058 ± 0.001ef | 0.392 ± 0.001fgh | 0.00 ± 0.00a | 97.04 ± 0.000j | 0.00 ± 0.00 | 2.51 ± 0.000c |

| E4 | 0.060 ± 0.002fg | 0.49 ± 0.002ij | 3.25 ± 0.007e | 89.18 ± 0.042c | 0.10 ± 0.00 | 7.02 ± 0.049k | |

| 14th | A5 | 0.060 ± 0.001fg | 0.39 ± 0.001de | 0.00 ± 0.00a | 96.43 ± 0.014h | 0.00 ± 0.00 | 3.12 ± 0.012e |

| E5 | 0.069 ± 0.001i | 0.391 ± 0.001ghi | 3.20 ± 0.028d | 91.59 ± 0.014d | 0.10 ± 0.00 | 4.65 ± 0.014i | |

| 20th | A6 | 0.031 ± 0.001b | 0.309 ± 0.003a | 0.00 ± 0.00a | 97.51 ± 0.042k | 0.00 ± 0.00 | 2.15 ± 0.038b |

| E6 | 0.041 ± 0.001d | 0.379 ± 0.001cd | 2.96 ± 0.014c | 92.01 ± 0.035e | 0.10 ± 0.00 | 4.51 ± 0.023h | |

| 26th | A7 | 0.027 ± 0.001a | 0.313 ± 0.001b | 0.00 ± 0.00a | 97.82 ± 0.014l | 0.00 ± 0.00 | 1.84 ± 0.011a |

| E7 | 0.034 ± 0.001c | 0.376 ± 0.003c | 2.83 ± 0.014b | 93.16 ± 0.028f | 0.10 ± 0.00 | 3.50 ± 0.010g |

Values are in mean ± standard deviation from triplicate determinations. The mean values with different superscript letters in the same row were significantly different (p < 0.05). A: experimental palm sap, (A1–A7) = samples of experimental palm sap analyzed at different categories of time interval (0th–26th h); E: palm wine analogue, (E1–E7) = samples of palm wine analogue analyzed at different categories of time interval (0th–26th h)

Mineral and vitamin content comparisons

Table 3 depicts the mineral and vitamin compositions of the palm wine analogue samples (E1–E7) and the experimental palm sap samples (A1 to A7). In experimental palm sap samples (A1 to A7), iron content ranged from 0.330–0.979 mg/100 mL, calcium content ranged from 64.50–81.00 mg/100 mL, and iodine content ranged from 0.054–0.230 mg/100 mL. In palm wine analogue samples (E1–E7), iron content ranged from 0.403–0.718 mg/100 mL, calcium content ranged from 46.00–67.50 mg/100 mL, zinc content ranged from 0.046–0.077 mg/100 mL, and iodine content ranged from 0.062–0.144 mg/100 mL. Likewise, in experimental palm sap samples (A1 to A7), vitamin A content ranged from 31.49–83.68 Iµ and vitamin C content recorded a range of 16.49 ± 0.028 mg/100 mL to 20.65 ± 0.014 mg/100 mL. In palm wine analogue samples (E1–E7), vitamin A content ranged from 36.0–75.88 Iµ, and vitamin C ranged from 2.76–4.17 mg/100 mL.

Mineral and vitamin compositions between palm wine analogue samples (E1–E7) and experimental palm sap samples (A1–A7) at various time intervals (0th–26th h)

| Time interval (hour) | Parameters samples | Iron (mg/100 mL) | Calcium (mg/100 mL) | Zinc (mg/100 mL) | Iodine (mg/100 mL) | Vitamin A (Iµ) | Vitamin C (mg/100 mL) |

|---|---|---|---|---|---|---|---|

| 0th | A1 | 0.968 ± 0.006l | 64.50 ± 0.707e | 0.027 ± 0.001a | 0.054 ± 0.000a | 83.68 ± 0.014n | 17.21 ± 0.014e |

| E1 | 0.421 ± 0.004d | 50.50 ± 0.707bc | 0.046 ± 0.001de | 0.062 ± 0.000c | 75.88 ± 0.021m | 3.41 ± 0.050b | |

| 2nd | A2 | 0.373 ± 0.012b | 67.00 ± 1.414ef | 0.049 ± 0.003ef | 0.060 ± 0.000b | 70.23 ± 0.021k | 17.30 ± 0.141e |

| E2 | 0.611 ± 0.002g | 67.50 ± 0.707f | 0.065 ± 0.000g | 0.068 ± 0.000d | 73.77 ± 0.007l | 2.76 ± 0.014a | |

| 5th | A3 | 0.979 ± 0.004l | 65.00 ± 1.414ef | 0.029 ± 0.004a | 0.080 ± 0.000f | 63.81 ± 0.035h | 20.65 ± 0.014h |

| E3 | 0.579 ± 0.001f | 52.50 ± 0.707c | 0.050 ± 0.002f | 0.077 ± 0.001e | 68.11 ± 0.028j | 4.13 ± 0.000c | |

| 9th | A4 | 0.330 ± 0.002a | 66.00 ± 0.000ef | 0.038 ± 0.002bc | 0.102 ± 0.000h | 61.72 ± 0.028g | 20.61 ± 0.042h |

| E4 | 0.403 ± 0.001c | 46.00 ± 0.000a | 0.053 ± 0.001f | 0.088 ± 0.000g | 64.58 ± 0.050i | 4.13 ± 0.000c | |

| 14th | A5 | 0.950 ± 0.004k | 81.00 ± 1.414h | 0.041 ± 0.004cd | 0.203 ± 0.000l | 56.73 ± 0.021f | 16.49 ± 0.028d |

| E5 | 0.718 ± 0.001i | 57.50 ± 0.707d | 0.077 ± 0.001h | 0.120 ± 0.002i | 37.61 ± 0.028e | 4.13 ± 0.000c | |

| 20th | A6 | 0.772 ± 0.003j | 75.00 ± 1.414g | 0.035 ± 0.001b | 0.215 ± 0.000m | 33.31 ± 0.035b | 18.60 ± 0.028f |

| E6 | 0.660 ± 0.006h | 51.00 ± 1.414bc | 0.063 ± 0.002g | 0.135 ± 0.000j | 36.87 ± 0.021d | 4.13 ± 0.000c | |

| 26th | A7 | 0.539 ± 0.001e | 67.00 ± 1.414ef | 0.029 ± 0.001a | 0.230 ± 0.002n | 31.49 ± 0.028a | 19.82 ± 0.021g |

| E7 | 0.578 ± 0.011f | 48.50 ± 2.121b | 0.051 ± 0.003f | 0.144 ± 0.000k | 36.00 ± 0.050c | 4.17 ± 0.007c |

Values are in mean ± standard deviation from triplicate determinations. Means differently superscripted along the horizontal rows are significantly different (p < 0.05). A: experimental palm sap, (A1–A7) = samples of experimental palm sap analyzed at different categories of time interval (0th–26th h); E: palm wine analogue, (E1–E7) = samples of palm wine analogue analyzed at different categories of time interval (0th–26th h)

Physiochemical, rheology, pH, and alcohol comparisons

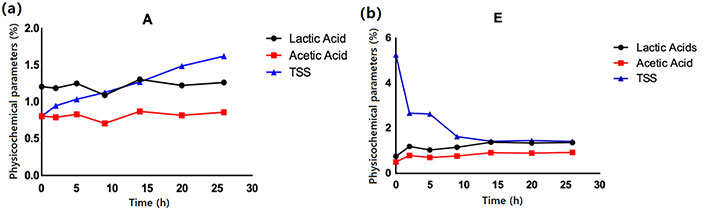

Figure 4 presented selected physiochemical parameters specific to acetic/lactic acids and TSS of palm wine analogue (E1–E7) and experimental palm sap samples (A1–A7) at varied time intervals (0th–26th h). Specifically, lactic acid values of experimental palm sap samples (As) ranged from 1.093–1.307, while those of palm wine analogue samples (Es) ranged from 0.759–1.389. Also, acetic acid values for As ranged from 0.710 to 0.872, whereas those of Es ranged from 0.509–0.931. TSS seemingly increased with time intervals 0th–26th h. Contrarily, consistent TSS decreases in Es happened as the time interval increased, except for E6.

Graphs showing changes in Lactic acid, Acetic acid, and Total Soluble Solid (TSS) of samples A and E with Time. Graphs (a and b) of selected physicochemical parameters specific to acetic/lactic acids and TSS of experimental palm sap samples (A1–A7) and palm wine analogue samples (E1–E7), respectively as examined at a varied time interval (0th–26th h)

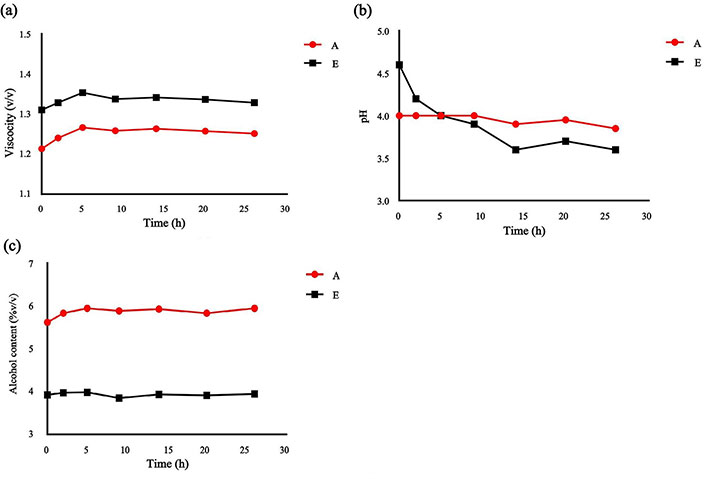

Figure 5a shows viscosities of samples (As and Es) increased from 0th h to 5th h, which suggests low internal temperature. Decreased viscosity would be anticipated from 14th h to 26th h, which suggests the performance efficiency of fermenting microbial entities. Figure 5b shows the pH of experimental palm sap samples (A1–A7) ranged from 3.85 to 4.0, while those of palm wine analogue samples (E1–E7) ranged from 3.60 to 4.60. The pH of As appeared stable initially until after the 9th h. Figure 5c shows alcohol content of palm wine analogue samples (E1 to E7) ranged from 3.91 % to 3.98% v/v, whereas those of experimental palm sap (A1 to A7) ranged from 5.62% to 5.94% v/v. At 26th h, the alcohol content of the palm wine analogue was 3.94 ± 0.00% v/v, and that of the experimental palm sap was 5.94 ± 0.014% v/v.

Changes in (a) viscosity, (b) pH, and (c) alcohol content of experimental palm sap samples (A) and palm wine analogue samples (E) as examined at a varied time intervals

Microbial and sensorial comparisons

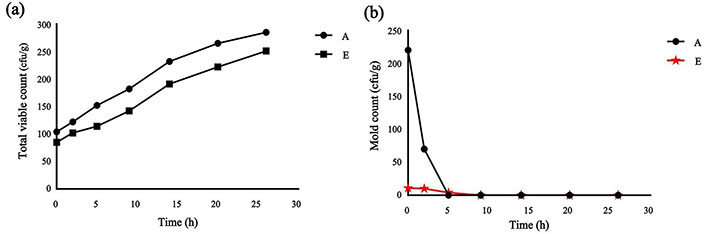

The TVC and mold count of palm wine analogue samples (E) and experimental palm sap samples (A), as examined at varied time intervals (0th–26th h), are shown in Figure 6a and Figure 6b. TVC (Figure 6a) using NA, and mold count (Figure 6b) using SDA, were detected at 10-2 and 10-1, respectively. Typically representative of the exponential phase of the microbial growth curve, the TVC for the experimental palm sap (A) increased continuously but initially, alongside those of the palm wine analogue (E). If the fermentation process had continued, the increasing TVC trends might have briefly progressed before entering the phases of stationary and death.

Total viable count (a) and mold count (b) of palm wine analogue samples (E) and experimental palm sap samples (A) as examined at varied time interval (0th–26th h)

Sensory scores of experimental palm sap, palm wine analogue, fresh tiger nut milk-sugar syrup beverage, and fresh palm wine by way of appearance, taste, flavor, clarity, aftertaste, consistency, tartness, mouthfeel, and overall acceptability are shown in Table 4. The flavor of fresh palm wine (8.05 ± 0.94) was preferred by the panelists, whereas those of fresh tiger nut milk-sugar syrup beverage (4.85 ± 2.03) were the least accepted. The aftertaste attribute score of fresh palm wine (7.65 ± 1.23) was preferred by the panelists over the others in the following order: experimental palm sap (7.25 ± 1.65), palm wine analogue (6.95 ± 1.67), with the fresh tiger nut milk-sugar syrup beverage (5.10 ± 2.47) as the least accepted. The tartness attribute score of experimental palm sap (7.50 ± 1.64) was preferred by the panelists over others, while the fresh palm wine (7.25 ± 1.89) was the least accepted.

Sensory evaluation data between palm wine analogue, experimental palm sap, fresh tiger nut milk-sugar syrup beverage, and fresh palm wine

| Samples/Parameters | Experimental palm sap | Palm wine analogue | Fresh tiger nut milk-sugar syrup beverage | Fresh palm wine |

|---|---|---|---|---|

| Appearance | 6.15 ± 1.78b | 7.20 ± 0.89c | 4.25 ± 2.00a | 8.45 ± 0.78d |

| Taste | 6.60 ± 2.21b | 6.50 ± 1.47b | 5.20 ± 2.53a | 7.95 ± 1.10c |

| Flavor | 6.45 ± 2.04b | 6.80 ± 1.40b | 4.85 ± 2.03a | 8.05 ± 0.94c |

| Clarity | 5.50 ± 2.14ab | 6.35 ± 1.66b | 4.60 ± 2.33a | 8.15 ± 0.99c |

| Aftertaste | 7.25 ± 1.65b | 6.95 ± 1.67b | 5.10 ± 2.47a | 7.65 ± 1.23b |

| Consistency | 6.45 ± 1.64ab | 6.85 ± 1.14b | 5.60 ± 2.46a | 8.15 ± 1.09c |

| Tartness | 7.50 ± 1.64b | 7.35 ± 1.57b | 4.25 ± 1.97a | 7.25 ± 1.89b |

| Mouthfeel | 6.90 ± 1.59b | 7.20 ± 1.28b | 5.80 ± 1.96a | 8.20 ± 1.00c |

| Overall acceptability | 6.65 ± 1.69b | 7.05 ± 1.05b | 5.50 ± 2.14a | 8.25 ± 0.79c |

Values are in mean ± standard deviation from twenty panelists (determinations). Means differently superscripted along the horizontal rows are significantly different (p < 0.05). CDA: experimental palm sap; MDE: palm wine analogue; SVN: fresh tiger nut milk-sugar syrup beverage; AEC: fresh palm wine

Discussion

Proximate compositions showed fluctuating values when comparing the analogue and experimental palm sap samples at various time intervals (refer to Table 2). Some decrease in crude fat also were found, which may suggest a catalytic activity, particularly in palm wine analogue. However, the fluctuating decreases and increases in moisture at experimental palm sap, alongside carbohydrate contents from A5 E5 to A7 E7, seemingly agrees with data of Bernalier et al. [17], where dietary carbohydrates become vulnerable to the bacterial attack that degrades into monomers. Moreover, dietary fibers function well in the alimentary canal of consumers, especially in the large intestine (colon) [11]. Considering the data generated from A5 E5 through A6 E6 to A7 E7, such increases and decreases in carbohydrate/moisture contents across 0th h, 2nd h, 5th h, and 9th h could reflect the inefficiencies at the lag phase of fermentation.

Mineral and vitamin compositions also showed fluctuating values when comparing the analogue and experimental palm sap samples at various time intervals (refer to Table 3). Considering the 14th–26th h intervals, the significant decreases in values of iron, calcium, zinc, and vitamin A appear not in agreement with published data of Davidsson et al. [18] that reported fermentation among useful alternatives to improve digestibility, nutrient densities, and bioavailability of micronutrients. Conversely, the decrease in vitamin A does agree with published data by Zubay [19] where vitamin A is converted to co-enzymes that actively work with enzymes to catalyze biochemical reactions. Notably, vitamin contents have long been understood to increase during the fermentation processes of palm sap [20], which appears to have happened in the current study at certain hours. Additionally, the continuous increases in iodine—an important micronutrient, from the 0th–26th h could also be a contributing factor.

Physiochemical parameters varied specific to acetic/lactic acids and TSS of palm wine analogue (E1–E7) and experimental palm sap samples (refer to Figure 4). Considering the differences in pH and viscosities (refer to Figure 5a and Figure 5b), more sugars would be needed for fermentative activities of lactic acid producers, which might relate to decreased medium viscosity [21]. As an example, dextran production could increase the viscosity of sugar solution, but more production of dextran could decrease it (viscosity of sugar solution) [22]. Murano [11] recognized that milk would sour with increased titratable acidity due to lactic acid production. Figure 5c shows promising ranges of alcohol content of palm wine analogue when compared to experimental palm sap (A1 to A7) samples. Some workers elsewhere have demonstrated alcohol contents to vary widely across palm wine analogues [21, 23]. Previously, Amoa-Awua et al. [12] showed increased alcohol content in market palm wine from 3% to over 7% in 24 h. Chandrasekhar et al. [13] reported increased alcohol content from 5% to 8% from palm wine samples specifically within a 12 h period.

The behavior of alcohol content somewhat connects with that of TVC and mold count of palm wine analogue samples (E) and experimental palm sap samples (A) (refer to Figure 6). TVC (Figure 6a) using NA, and mold count (Figure 6b) using SDA, were detected at 10–2 and 10–1, respectively. Besides, nutrient availability, water activity, pH, oxygen content, and the nature of food would facilitate microbial proliferation [11]. Also, the mold counts equally reflected the expected trend in a typical media undergoing fermentation. As alcohol contents (of samples A and E) gradually increased, the mold count in turn tended to decrease. Justifiably, the alcohol strength would be critical to control mold growth [24]. Species of Saccharomyces yeast to thrive in grape juice should produce alcohol as its metabolic by-product. Above 20% alcohol should impede mold survival, which reflects its preservative action.

Sensory scores showed promising levels of acceptance when comparing experimental palm sap, and palm wine analogue (refer to Table 4). Indeed, fresh palm wine or not-so-fermented palm wine was preferred by the panelist having an overall acceptability score of 8.25 ± 0.79. The sensory attributes of experimental palm sap were preferred by the panelist, over fresh tiger nut milk-sugar syrup beverage (5.50 ± 2.14). As a potential target product, the palm wine analogue would be compared to the commercially available palm wine. The fermentation process largely delivers such compounds like carbonyls, phenols, and nitrogen that shape the organoleptic attributes especially aroma and flavor, which help in the eventual shelf preservation of the palm wine [8, 25].

In conclusions, the drive for a sustainable alternative led to the evaluation of palm wine analogue produced from different blends of tiger nut milk and sugar syrup. The unfermented tiger nut milk appeared with very minimal palm wine odor as attribute. Further, the observed palm wine features developed from microbial activities were probably influenced by the inoculum (palm wine dregs), which would likely reflect the production of such organic compounds as ethanol and organic acids (lactic acid and acetic acid). The control (experimental palm sap: A) seemed not to differ significantly when compared to inoculated sample (palm wine analogue: E). Considering all the analyses, from proximate compositions, microbiological, and physicochemical, to sensory evaluation, the control appeared to somewhat resemble those of the experimental samples of this study. Further, the sensory scores appear to strengthen the case that palm wine analogue competes favorably with natural palm wine.

Potentially, the (palm wine) analogue produced from tiger nut milk and sugar syrup blends using palm wine dreg as inoculum could be embraced by the market as natural palm wine. Indeed, the emergent product can serve as an alternative sustainable promise for palm wine, which could help fill the market supply gap, especially in seasons of reduced supply/yield. Moreover, in order to prevent spoilage and ensure the quality of palm wine analogue produced from tiger nut milk and sugar syrup blends, further microbial techniques like enzyme-linked immunosorbent assays (ELISA) and polymerase chain reactions (PCR) are required, which would help identify pathogens, as well as establish some it is antimicrobial properties. Also, future work could explore palm wine analogues that come from other nut milk and sugar syrup blends and make comparisons to seek the best options for the consumer market.

Abbreviations

| NA: | nutrient agar |

| SDA: | saboraud dextrose agar |

| TSS: | total soluble solids |

| TVC: | total viable count |

Declarations

Author contributions

AOO: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Writing—original draft. GIO: Conceptualization, Data curation, Formal analysis, Investigation, Methodology, Project administration, Supervision, Writing—original draft. CFO: Data curation, Formal analysis, Investigation, Methodology, Writing—original draft. OCN: Data curation, Formal analysis, Investigation, Methodology. QNO, MIH, SJ, and KL: Software, Validation, Visualization, Writing—review & editing. CORO and MK: Supervision, Validation, Visualization, Writing—review & editing. RPFG: Validation, Supervision, Visualization, Writing—review & editing. All authors reviewed and approved the final manuscript.

Conflicts of interest

Charles Odilichukwu R. Okpala who is the Editorial Board Member of Exploration of Foods and Foodomics had no involvement in the decision-making or the review process of this manuscript. The other authors declare that they have no conflicts of interest.

Ethical approval

Not applicable.

Consent to participate

Prior to the sensory evaluation activity, the use of verbal consent was applied to panel members as per routine (departmental) activity and approved by an Internal Review Committee within the Department of Food Science and Technology, the University of Nigeria Nsukka.

Consent to publication

Not applicable.

Availability of data and materials

The datasets generated and/or analyzed during the current study are available from the corresponding author upon reasonable request.

Funding

Authors SJ, KL, and MK appreciate the financial support from Wrocław University of Environmental and Life Sciences-Poland. Author RPFG appreciates financial support from the Polytechnic Institute of Viseu-Portugal. The funders had no role in study design, data collection and analysis, decision to publish, or preparation of the manuscript.

Copyright

© The Author(s) 2025.

Publisher’s note

Open Exploration maintains a neutral stance on jurisdictional claims in published institutional affiliations and maps. All opinions expressed in this article are the personal views of the author(s) and do not represent the stance of the editorial team or the publisher.