Abstract

Aim:

This research was conducted on the hypothesis that refined sugars negatively affect health, require high energy for production, generate significant carbon emissions, and produce environmental waste. Additionally, by-products such as molasses and pulp, which are often underutilized, can be repurposed as value-added products for human consumption. This research focuses on a new, long-shelf-life product derived from sugar beet. The developed product retains nutrients such as protein, fiber, vitamins, and minerals that are naturally present in sugar beet.

Methods:

The new method proposes using the entire beet as an unrefined alternative to refined sugar. The processing steps include cleaning, cooking, peeling, shredding, drying, and grinding. Various cooking methods were tested, and the optimum conditions were found to be 4.5 hours at 165°C. To prevent oxidation of peeled beets, a 0.5% citric acid solution was applied for 15 min at 25°C prior to cooking. Drying was performed in a convection oven with pans at 95°C for 7.5 hours.

Results:

The final product had a moisture content of 2.9% and a water activity level of 0.302. The product contained 78.6% total sugars, 12.9% fiber, and 3.45% protein, and was classified as an unrefined sweetener rich in both protein and fiber. Compared to the typical yield of 120 g of refined sugar from 1 kg of beets, this new method produces 219 g of product by utilizing fibers, proteins, and other nutrients, along with by-products such as molasses and pulp.

Conclusions:

Due to its high fiber and protein content, the new product has a low glycemic index. Compared to conventional beet sugar production, the proposed method reduces energy consumption and carbon emissions by 40% per unit of product. The new input obtained has a high potential to be used as a source of sugar and fiber in bakery and confectionery products. It is a more sustainable process than refined sugar.

Keywords

Beet pulp, beet sugar, dried beet, molasses, sugar beetIntroduction

Sugar beet (beta vulgaris) is a biennial agricultural plant from the spinach family. The composition of beet includes vitamins A, B, C, and P, and minerals such as zinc, sodium, magnesium, potassium, calcium, iron, phosphorus, and bromine [1]. The chemical composition of sugar beet is given in Table 1 [2].

The average chemical compositions of sugar beet

| Nutrients | Average (%) |

|---|---|

| Moisture | 77.30 |

| Total carbohydrate | 18.33 |

| Protein | 0.51 |

| Total dietary fibre | 2.41 |

| Lipids | 0.15 |

| Minerals | 0.53 |

| Vitamins | 0.09 |

| Nitrogenous substances | 0.08 |

| Ash | 0.60 |

Sugar, which enhances the flavor of many foods and drinks, is not commonly consumed in its natural plant form. Therefore, sugar beet must undergo a series of processes to extract the sugar and make it consumable. Sugar production is typically carried out in large industrial facilities because the extraction process involves many complex steps. Today, both in our country and worldwide, crystallized sucrose is primarily produced from sugar beet. For this purpose, sugar beets are harvested and processed in sugar factories using traditional methods. Once most of the sugar is extracted, molasses and fresh beet pulp are obtained as by-products, in addition to the refined sugar. The sugar yield from sugar beet is typically around 10–20% of its total fresh beet weight. Molasses, a thick brown liquid with a dry matter content of around 80%, is one of the by-products. Approximately 50% of molasses is sugar, while the remaining 30% consists of organic substances and salts. Molasses also contains various minerals and water-soluble compounds, including sucrose, inverted sugar, raffinose, pectin degradation products, lactic acid, and nitrogenous substances. Despite its high sugar content, reprocessing molasses to extract this sugar is not economically feasible. Instead, molasses is widely used in the fermentation industry, particularly for the production of ethyl alcohol, spirits, bread yeast, and citric acid. It is also a key ingredient in the animal feed industry [3]. Fresh beet pulp is a valuable animal feed with a lignocellulosic base and is widely used as animal feed, either directly as fresh and/or dry pulp or mixed with molasses. Dried beet pulp contains significant amounts of protein, fat, sucrose, calcium, magnesium, sodium, potassium, soluble and insoluble fibers, and other polysaccharides (such as hemicelluloses, pectins, and cellulose) [4, 5]. It is also rich in terms of other mineral substances and amino acid diversity and quantities. Fresh sugar beet by-products are also used as substrates for biogas and bioethanol production. Obtaining sugar from sugar beet requires a series of processes that are quite long, energy and water-consuming. In addition, high amounts of limestone and some chemicals are used in some process stages [6–8]. The ratios of moisture, sugar, and non-sugar components found in sugar beet are given in Table 2. Accordingly in molasses, which are by-products based on dry matter, there is 1.5%, and in pulp, 0.6% of sugar cannot be extracted in the process [9]. The newly developed ingredient also eliminates these sugar losses and does not require a refining process.

Mass balance in the sugar beet production

| Products | Processing 100 kg sugar beet | |||||

|---|---|---|---|---|---|---|

| Amount (kg) | Moisture (kg) | Dry matter (kg) | Sucrose (kg) | Protein (kg) | Fibers + others (kg) | |

| Sugar beet | 100 | 77.24 | 22.76 | 18.33 | 2.21 | 2.22 |

| Sugar | 15.50 | 0.68 | 14.82 | 14.82 | 0 | 0 |

| Molasses | 3.10 | 0.56 | 2.54 | 1.27 | 0.51 | 0.76 |

| Dried pulp | 6.00 | 0.60 | 5.40 | 2.24 | 1.70 | 1.46 |

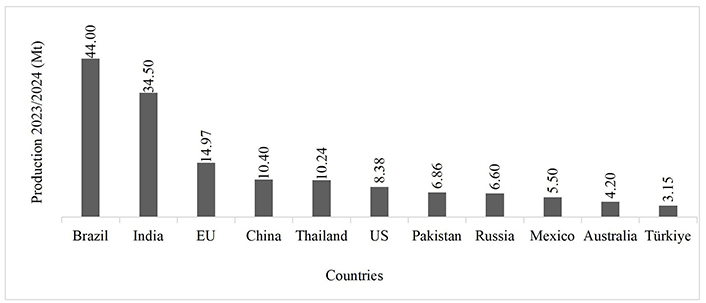

The cooking process comes into play when sugar beets are turned into syrup. At this stage, unwanted saponins [10] and bitter and/or odorous substances in sugar beets are released and polyphenol oxidases that cause darkening are inactivated [11]. In the 2023/2024 period, 183.5 million tons of sugar were produced in the world. Production is expected to reach 202 million tons in 2033 and Türkiye produced 3.15 million tons of sugar [12]. Twenty-two million tons of sugar beet was harvested in Türkiye in the 2023/2024 season. The graph in Figure 1 lists the largest sugar producers in the world in the 2023/2024 season. Brazil has the largest share in world sugar production with 44 million tons. Türkiye ranks 11th after Australia with 3.15 million tons.

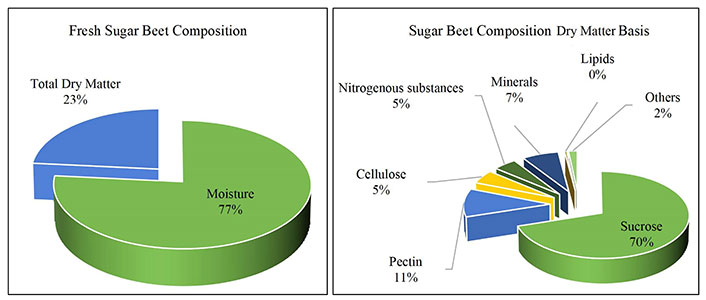

Refined sugar, which is obtained through long processes, is used intensively in the sugary food and beverage industry and in-home consumption. For human life, nutrients such as carbohydrates, proteins, fats, minerals, and vitamins must be taken in certain proportions. It is recommended that a normal person consumes an average of 120 g of protein, 40–80 g of fat, and 300–400 g of carbohydrates per day [10, 13]. Carbohydrates, categorized into three groups monosaccharides, disaccharides, and polysaccharides primarily cellulose, hemicellulose, and pectin provide 60–70% of the energy required by humans. They are also classified based on their molecular structures. Sucrose, one of the most widespread disaccharides in nature, has been available in daily human life for many centuries [14]. Recent studies indicate that the per capita consumption rates of sugar and other sweeteners are increasing worldwide. However, this trend raises concerns as excessive consumption can lead to long-term health issues such as diabetes, obesity, and cardiovascular diseases. The health effects of refined sugar, along with sweeteners used as sugar alternatives, are actively discussed in current research [15–18]. The fact that the ingredient developed as a result of this research is unrefined and contains other nutrients will reduce the concerns mentioned. The necessity of processing sugar beet in 3–4 months after harvest, the shortness of the harvest season, and its high water content (70–90%), which makes it easily perishable, bring about storage and quality problems [19]. During storage, significant quality losses occur as a result of biochemical transformation into less sweet components (trisaccharides such as raffinose) [20–22]. The pulp and molasses resulting from the refined sugar process also cause additional sugar, fiber, protein, mineral, etc. nutritional losses [23]. The unique value of this study lies in the fact that, in addition to the sugar content of the beet, other nutritional elements are retained in the ingredient [24]. Due to the nutrients it contains, pulp is used as a valuable animal feed in wet form. Molasses is a preferred by-product of fermentation processes due to its high sugar content and valuable nutrients, comprising approximately 50% sucrose, 80% dry matter, and a range of minerals, vitamins, and other organic compounds. It is generally used in the animal feed industry and the production of yeast, citric acid, alcohol, rum, and pharmaceuticals [25]. In Figure 2, the approximate moisture and dry matter ratios of fresh sugar beet are given in the left graph and the ratios of the components in the right graph are given in terms of dry matter.

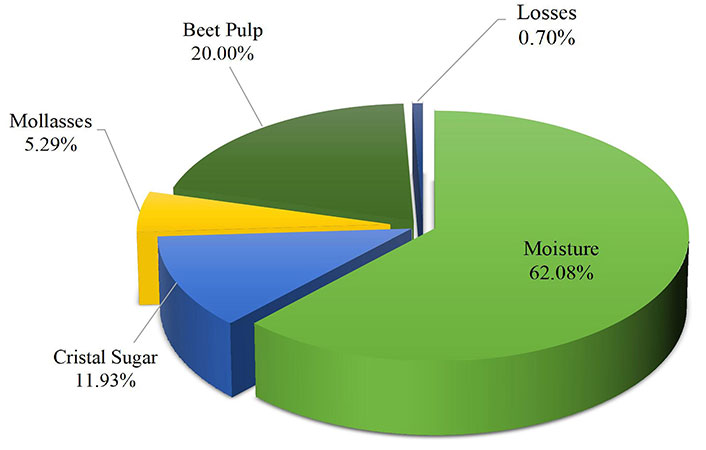

When sugar beet is processed to produce crystal sugar, some by-products are also produced. These products are converted into different products with additional processes or are used as animal feed [26–28]. Figure 3 shows the approximate proportions of sugar and by-products resulting from the processing of sugar beet. As can be seen from the figure, approximately 20% of pulp (animal feed) and 5.29% of molasses are produced as by-products. Molasses can be used as a semi-finished product in the food, beverage, and chemical industries, while pulp is mostly used as animal feed. There are also limited studies on its use as a food ingredient due to its high nutritional content [29–31]. In food applications, it is known that the life of the pulp is very short without processing [32] and that it releases a bad odor into the environment with fermentation. The newly developed food ingredient is aimed to eliminate these two important byproducts to a large extent.

Materials and methods

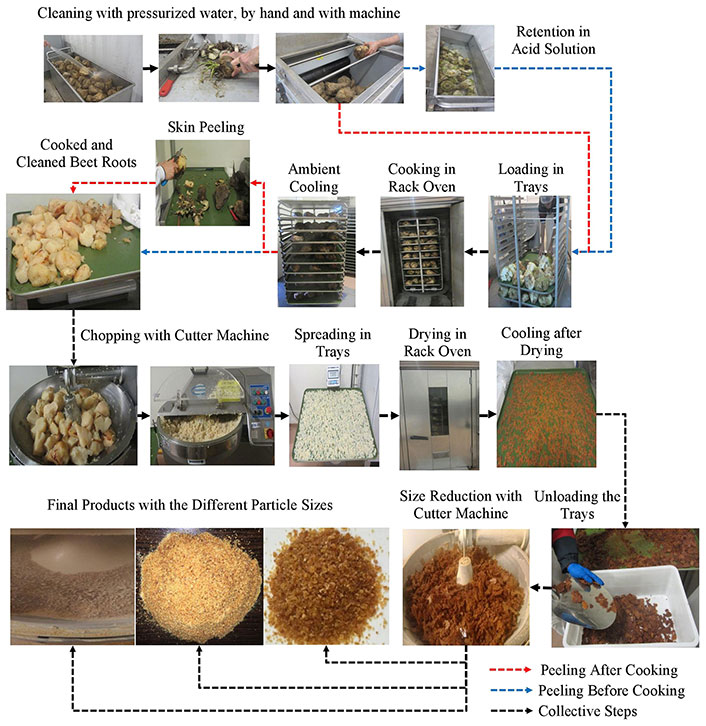

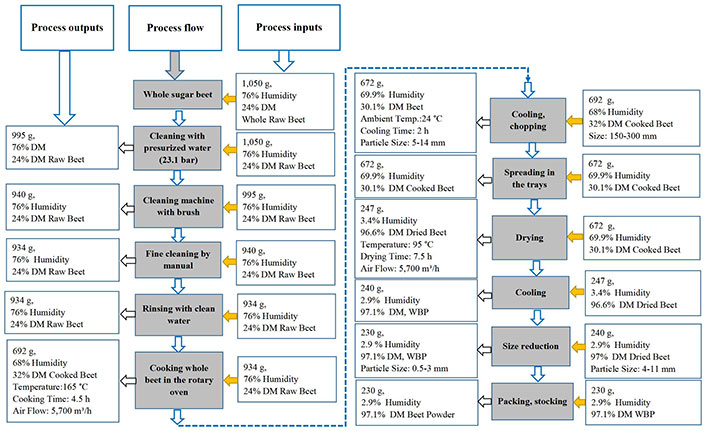

In this study, sugar beets sourced from the Eskişehir Province of Türkiye were used as the experimental material. All cleaned beets were utilized in the experiments, both with and without peeling. The study was initiated to address several issues: sugar beets tend to rot shortly after harvest, leading to low yield, long processing times, certain nutrients (such as fiber, vitamins, and minerals) are not easily accessible for human consumption, and the negative environmental effects of waste. The production method for dried sugar beets involves several steps: cleaning the beets of external residues, cooking the cleaned beets, peeling the cooked beets, breaking them into pieces, and drying them to the desired size. During the collection of the beets, the heads are cut off, or the leaves are roughly separated. In this study, the cleaned and peeled beet stem is referred to as the whole beet. The process steps and flowchart for the food ingredient known as cooked and dried whole beetroot powder (WBP), which is the focus of this study, are illustrated in Figure 4. Two different methods were employed:

Peel the beetroot before cooking, followed by acid treatment and cooking.

Cook the beetroot with its peel, then peel it afterward.

In the cooking process, various methods were tested in preliminary trials, including boiling in water, steaming, microwaving, and using a rotary convection oven. The rotary convection oven with a pan was chosen due to its similar effects on the quality of the cooked product and ease of use. The post-cooking peeling method was preferred over the pre-cooking method due to the need for waiting in an acid solution, which introduced a risk of contamination from external sources. The product qualities after cooking were found to be similar for both methods. The flow of both methods is presented in Figure 4, accompanied by product images. The method indicated with red arrows represents the peeling after cooking, while the method marked with blue arrows shows the peeling before cooking. The steps shown with black arrows indicate the steps used in both methods.

To dry the ingredient, preliminary experiments were carried out at different temperatures and drying times in the laboratory to reach the targeted 3% (g/100 g) moisture value for the long shelf life. As a result of the preliminary experiments, it was understood that the temperature range could be applied between 90°–110°C and the drying time between 5–8 hours. Cooked beet moisture and temperature were kept constant, and the experimental conditions were created as a response to moisture with the design expert program as variable drying time and temperature. The program suggested 16 different conditions and it was understood that the desired moisture value was reached at the most optimum time at 7.5 h and temperature 95°C (Table 3, Run:14).

Test variables and responses

| Run | Factor 1: temperature (ºC) | Factor 2: drying time (h) | Response 1: moisture (g/100g) |

|---|---|---|---|

| 1 | 90 | 6.5 | 3.8 |

| 2 | 105 | 8.0 | 2.4 |

| 3 | 110 | 5.5 | 3.4 |

| 4 | 110 | 6.5 | 2.8 |

| 5 | 105 | 5.0 | 3.9 |

| 6 | 103 | 7.0 | 2.8 |

| 7 | 90 | 8.0 | 2.7 |

| 8 | 98 | 6.5 | 3.3 |

| 9 | 90 | 5.0 | 4.6 |

| 10 | 105 | 8.0 | 2.5 |

| 11 | 104 | 6.0 | 3.3 |

| 12 | 105 | 5.0 | 3.9 |

| 13 | 98 | 6.5 | 3.3 |

| 14 | 95 | 7.5 | 2.9 |

| 15 | 98 | 6.5 | 3.3 |

| 16 | 110 | 6.5 | 2.7 |

Both methods are used and the process conditions and flow are given in detail in Figure 5. Here, the tests were started by using 1,050 g of fresh beetroot containing 76% moisture. After cleaning with pressurized water, the amount decreases to 995 g, and after brush cleaning, it decreases to 940 g. After manually separating the root and leaf residues, the amount decreases to 934 g. Using a natural gas-fired, rotary convection oven with a pan [33]. The mass of beetroot after cooking in the temperature range of 150°–180°C is obtained as 692 g. After cooking for 4–5 hours, the moisture content of the beetroot is measured as 68% and the dry matter content as 32%. After cooling the cooked beets for 2 hours under ambient conditions and peeling their skins, 672 g of cooked beetroot with 30.1% dry matter content is obtained at 24°C. The beets, weighing 672 g with a 30.1% dry matter content, are cut into 5–14 mm intervals, laid on drying oven pans, and dried at 95°C for 7.5 hours. After drying, they are cooled under ambient conditions and 240 g dried beetroot with 3% moisture content is obtained at 24°C. Depending on the intended use, these dried beets are ground with a hammer mill to obtain cooked and dried WBP with 3% moisture and 0.5–3 mm grain size. The total sugar content of the obtained dried beetroot powder is 78.6%, the total fiber content is 12.9%, the protein content is 3.9%, and, a new food ingredient with a high mineral content with an efficiency of 21.9% (230/1,050 g/g), low tendency to clump, and long shelf life is obtained.

The process flow of cooked and dried WBP with process parameters. DM: dry matter; WBP: whole beetroot powder

The whole sugar beet cooking and drying process steps are carried out in the following order in the flow.

Washing: in the subject of the study, cooked sugar beet dry and production method, sugar beets are first cleaned from external contamination such as soil. With this process, the residues on the shell of the whole sugar beet are cleaned by washing machines [34] and foreign materials such as mud and soil that come with the beet are separated from the beet. The quality of the water used during the washing process is important in terms of not containing odorous components. In addition, the flow rate, amount, and duration of the washing water are kept at an optimum level to ensure complete cleaning of the sugar beet.

Cooking: unwanted substances such as saponins, bitter compounds, and odorous components are released, while polyphenol oxidases responsible for darkening are inactivated. Several alternative methods can be applied during the cooking phase, with the following cooking time:

Cooking in the water (with or without skins): 2–4 hours.

Steam cooking (with or without skins): 2–6 hours.

Microwave cooking (with or without skins): 45–130 min, depending on the applied power level.

Rotary convection oven (whole beets): 4.5 hours at 165°C.

Cooling: after cooking, the beets are kept until they reach ambient temperature (24°–25°C).

Chopping: the cutting process can be done in the desired size and shape. Thus, the surface area of the cut beet pieces increases, making it easier to dry. If the cutting process is desired before cooking, the washed and cleaned beets are first peeled and cut into the desired size and shape. In the production method where the cooking process will be applied to unshelled sugar beets: to prevent them from darkening during cooking, they are immersed in organic acids such as 0.5% citric acid, malic acid, and reducing agent solutions for 10–20 min. Afterward, the desired cooking alternative, drying, and grinding processes are applied, respectively.

Drying: in this trial, the drying process was carried out in a rotary oven with convection heating. It is also possible to use steel belt tunnel ovens for drying.

Grinding: the purpose of grinding is to bring the dried sugar beet to the desired size. Optionally, dried sugar beet can be turned into powder, grain, or flake. The drying time was optimized as 7.5 hours at 95°C and the desired 3% moisture value was reached without caramelization. It is known that when high caramelization color and aromas are desired, it is necessary to exceed 110°C [35–37].

Results

At the end of the study, a new unrefined food ingredient (sugar ratio 78.6%, total fiber ratio 12.9%, protein ratio 3.45%) with long shelf life which can be used as a sugar alternative was obtained. It is anticipated that the newly developed ingredient can be widely used in the food and beverage industry as a sugar alternative. In addition, it is assumed that the new ingredient will cause less energy consumption, less waste, and lower carbon emission due to the elimination of by-products and the less processing required. The drying process can be carried out at different temperatures according to the desired aroma components in the final product. Due to the high sugar content, caramelization and Maillard reactions [38, 39] can be carried out with heat application. If it is desired to reveal caramelized aromas in dried beetroot, the drying temperature and drying time can be changed [40] when it is not desired to reveal caramelized aromas in cooked whole dried beetroot: the drying process is carried out at lower temperatures. The moisture content of the newly developed ingredient was provided as 2.9 g/100 g and the water activity was 0.302. As a result, it was determined that it would have a shelf life of at least 2 years under appropriate storage conditions. The drying process also eliminates a large portion of the odors such as soil odors that occur in the natural structure of sugar beet during the cooking process. It is anticipated that the dried sugar beet obtained will bring additional structural features and aroma components to the products to be used. As can be seen from Table 4, the research subject, dried whole beet, as an alternative to refined sugar, contributes to fiber, protein, and minerals in addition to its high sugar content.

Whole beetroot powder composition

| Nutrients | Value |

|---|---|

| Protein (%) | 3.45 |

| Fat (%) | 0.08 |

| Total sugar (%) | 76.80 |

| Sucrose (%) | 72.80 |

| Glucose (%) | 1.80 |

| Fructose (%) | 2.20 |

| Total fiber (%) | 12.90 |

| Soluble dietary fiber (%) | 0.75 |

| Insoluble dietary fiber (%) | 12.15 |

| Calcium (mg/100g) | 150 |

| Magnesium (mg/100g) | 200 |

| Potassium (mg/100g) | 700 |

| Sodium (mg/100g) | 200 |

The average main nutrients of the developed food ingredient compared to sugar beet are given in Table 4. Accordingly, it is seen that the average sugar content is 76.8%, the total average fiber content is 12.9%, and the protein content is 3.5%. It is also possible to define this ingredient as a sweetener with high fiber and protein content.

Discussion

The author also has a patent (2018-GE-557427) regarding food products developed using the food input obtained as a result of the research [41]. When the existing studies in the literature are examined, there are limited studies on the evaluation of molasses and beet pulp, which are mostly beet by-products. No studies have been found investigating the dried cooked whole beet, which is the subject of this research. When the studies conducted on food are examined: it seems that some components found in sugar beet may contribute to texture, nutrients, health, digestion, and physicochemical properties. Examples of some studies in the literature are summarized below.

Lin et al. [42] thermomechanically micronized sugar beet pulp: study on its separation mechanism, physicochemical properties and emulsifying properties. They micronized sugar beet pulp into fibrous particles by ultrasonication and concluded that it improved the emulsifying capacity of beet pulp. Huang et al. [43] investigated the effect of the high-pressure homogenization method on sugar beet pulp. It was found that some of the insoluble dietary fibers were converted into soluble dietary fibers by high-pressure homogenization. It was found that the water and oil retention capacity of the fibers increased with the increase in homogenization pressure, and the melting temperature and crystallization tendency were reduced Daliri et al. [44]. Based on the strong relationship between intestinal dysbiosis and diabetes, they worked on the hypothesis that beetroot consumption may have direct antidiabetic effects by inhibiting carbohydrate-digesting enzymes. Fermentation, enzyme application, and thermal applications have studied the antidiabetic activity of beetroot. Ahmed et al. [45] studied the method of drying beetroot in thin slices with a microwave for energy optimization. In the study, they studied the drying performance of beetroot slices with different geometries by applying microwaves at different powers. It was determined that the time to reach the desired final moisture level was shortened with increasing power. It was noted that the drying speed was directly proportional to the microwave power, and the drying time was inversely proportional to the decreasing speed period. Dranca and Mironeasa [46] the effect of drying pretreatment and extraction processes on the yield and physicochemical properties of pectin obtained from bagasse, a by-product of sugar beet processing, was evaluated. Mella et al. [47] studied the effects of drying under a vacuum on the drying and functional properties of beetroot. It was stated that vacuum drying preserved the nutritional properties of beetroot better than freeze drying. It was shown that increasing the temperature increased the drying speed and significantly shortened the drying time. In this study, it was determined that vacuum drying at 50°C could be an alternative to freeze drying. Raikos et al. [48] investigated the effects of processed beetroot as a natural antioxidant in mayonnaise: stability, texture, and sensory properties. The effects of processed beetroot-added mayonnaise on oxidative and physical stability were investigated and compared with a control (mayonnaise without beetroot) and a commercially available product. All textural parameters were found to increase with the addition of beetroot. It was concluded that mayonnaise added with beetroot did not cause any significant change in sensory properties such as roughness etc. Filipovic et al. [49] studied the effect of the type and amount of sugar beet fibers on bread properties. The study investigated the effects of modified and unmodified sugar beet fibers on dough and bread yield, bread volume, and bread crumb quality. It was determined that with the increase in fiber content, dough, and bread yield increased but bread volume and bread crumb tendency were negatively affected. Mitrevski et al. [50] studied the effect of beetroot powder additives on the functional properties and shelf life of biscuits. Beetroot an excellent source of biologically active compounds, is considered to have highly beneficial effects on health. This research aimed to evaluate the effect of replacing einkorn flour with 15%, 20%, and 25% beetroot powder. The physicochemical and functional properties of biscuits baked at different temperatures (150°C and 170°C) were monitored initially and after 3 and 6 months of storage as standard conditions. The obtained results showed that biscuits enriched with beetroot powder had significantly improved functional, nutritional, and antioxidant potential during storage. Djordjević et al. [51] the effect of the addition of sugar beet and apple fiber combined with hydroxypropylmethylcellulose (HPMC) as a functional ingredient in gluten-free formulations on rheological, technological, and sensory properties was investigated. Gluten-free dough consistency increased when sugar beet and apple fiber were combined with HPMC. Gluten-free breads containing apple fiber formed higher volumes and softer crumb textures. The presented study investigated the effect of the addition of HPMC, sugar beet fiber, and apple fiber combined with sufficient water levels on gluten-free dough rheology, bread quality, and sensory properties. Gluten-free bread containing sugar beet fiber or apple fiber (AF) achieved attractive crust and crumb color and good sensory properties. Filipčev et al. [52] made products with molasses additives to increase the nutritional and processing properties of gluten-free cookies. Molasses-enriched gluten-free cookies increased micronutrients, antioxidant capacity, and phenolic compounds. Molasses addition slightly increased the hydroxymethylfurfural content in cookies but did not exceed the values defined for this type of product. It was stated that molasses addition increased the overall liking level of gluten-free cookies by 30%. Filipčev et al. [53] studied the use of sugar beet molasses in the processing of gingerbread-type cookies. Effect of molasses use on quality characteristics, nutritional profile, and bioavailability of calcium and iron to investigate the possibility of using sugar beet molasses in creating nutritionally improved gingerbread-type cookies, various types of cookies were prepared in which 25%, 50%, or 100% of honey was replaced by molasses. The substituted cookies were significantly higher in protein and ash than the reference. The use of molasses instead of honey in cookies resulted in a significant increase in the content of K, Ca, Mg, and Fe compared to the control. Considering all the investigated quality characteristics, it was recommended to substitute honey up to 50% in the gingerbread formulation.

In conclusion, the developed ingredient is produced from dried whole sugar beet and contains high levels of total sugars (sucrose, glucose, and fructose), protein, fiber, vitamins, and minerals. It consists of 21.9% whole sugar beet and is an unrefined, minimally processed ingredient. It is also believed that its glycemic index will be significantly lower than that of refined sugar. Sugar beet has a short harvest period, a high water content (70–90%), and a short shelf life. Due to the large volume occupied by fresh sugar beet, it cannot be stored without losing its quality unless it is processed. Using nearly all available methods and materials, the entire sugar content is preserved in the product. Additionally, minerals such as calcium, magnesium, potassium, and sodium are included in the ingredient. The heat treatment applied to the beet removes most of the unpleasant earthy taste and odor found in its natural state. The final product has a moisture content of 2.9 g/100 g and a water activity value of 0.302, giving it a shelf life of at least two years under normal conditions. This ingredient will contribute to sustainability through fewer process steps, no need for processing aids, reduced energy use, lower carbon emissions, decreased water consumption, faster processing, higher efficiency (21.9%), and less waste and by-products. Most notably, assuming 20% of the world’s sugar production comes from sugar beet, with an average sugar yield of 11.93% by utilizing molasses and pulp by-products from 305.8 million tons of sugar beet, 30.3 million tons of valuable nutrients with 2.9% moisture could be used for human consumption. The developed ingredient will find applications in a wide range of products, including chocolate, cream, food fillings, jams, jellies, marmalades, baked goods, and certain beverages due to its low moisture content, ease of processing, and high nutritional value. Furthermore, it will be possible to produce unique ingredients with varying flavors and colors by adjusting drying temperatures and times, promoting caramelization and Maillard reactions. When the method described in the research is examined, it becomes clear that the processes up until the cleaning stage of the beet are similar to those in conventional sugar production from beet [54, 55]. In the conventional method, significant amounts of energy and process aids, such as limestone, are used after the cleaning stage. It has been reported that approximately 0.25 tons of limestone is required for every ton of beet sugar produced [56]. Additionally, the energy consumption during the process is stated to be 28 kWh per kg of beet sugar [57]. A comparison can be made by assuming that the process stages of the proposed method and the conventional method are identical until after cleaning. According to the flow and mass balances shown in Figure 5, it is calculated that 10.94 kWh of energy is required to process 1 kg of dried beet in the proposed method. This is about 39% of the energy used in the conventional method. Since the pulp and molasses are directly utilized in the proposed method, energy consumption, and carbon emissions could be significantly reduced by eliminating the need to reprocess these by-products. Furthermore, the proposed method eliminates the need for limestone. The reduction in carbon emissions not only results from avoiding the processing of by-products but also from the 40% reduction in energy use during the process. It is anticipated that the proposed method can be integrated into existing beet sugar production processes worldwide with minimal investment, allowing both methods to operate simultaneously. The proposed method could be implemented sequentially by adding equipment such as continuous tunnel ovens, automatic peeling machines, cutter-like mincing machines, steel-belted continuous drying ovens for final drying, grinding mills, and screening systems, all of which would follow the cleaning stage.

Abbreviations

| HPMC: | hydroxypropylmethylcellulose |

| WBP: | whole beetroot powder |

Declarations

Author contributions

AG: Conceptualization, Methodology, Software, Data curation, Writing—original draft, Visualization, Investigation, Supervision, Validation, Writing—review & editing.

Conflicts of interest

The author declare that there are no conflicts of interest. AG filed a patent application regarding Cooked Sugar Beet-Sweetened Food Products (original Turkish: Pişmiş şeker pancarı ile tatlandırılmış gıda ürünleri) described here. The patent number is 2018-GE-557427. The patent is of no financial interest to the subject matter and material of the manuscript.

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent to publication

Not applicable.

Availability of data and materials

The raw data supporting the conclusions of this manuscript will be made available by the authors, without undue reservation, to any qualified researcher.

Funding

This study did not receive any specific grant from funding agencies in the public, commercial, or not-for-profit sector.

Copyright

© The Author(s) 2025.

Publisher’s note

Open Exploration maintains a neutral stance on jurisdictional claims in published institutional affiliations and maps. All opinions expressed in this article are the personal views of the author(s) and do not represent the stance of the editorial team or the publisher.