Abstract

Aim:

Kenaf (Hibiscus cannabinus) is an herbaceous plant of economic significance, the seed is rich in essential nutrients and has the potential for the production of protein-based products. This study investigated the holistic effects of coagulants, kenaf seed-to-water ratio for extraction, and temperature of addition of coagulant on the physicochemical and texture quality of kenaf seed tofu.

Methods:

Randomised full factorial design was used to obtain different formulations of kenaf seed tofu production under 4 factors at different levels.

Results:

The main factors of coagulant types, seed-to-water ratio and temperature of addition of coagulant significantly affected the yield, pH, crude protein, crude fat, lightness, yellowness and cohesiveness of the kenaf seed tofu while the redness of the tofu was significantly affected by the coagulant types only. However, the hardness, chewiness and springiness of the tofu were affected by coagulant types and concentrations. Additionally, the 2-way interactions significantly affected the texture profile of the tofu. Though, the 3-way and 4-way interactions have no significant effect on the texture characteristics of the kenaf seed tofu.

Conclusions:

The tofu made with aluminium potassium salt at concentrations of 0.50 g/100 mL and 1.00 g/100 mL, and 80°C temperature of addition of coagulant formed the highest yield of 71.22 g/100 g and 77.57 g/100 g, respectively. This study also found that aluminium potassium salt and glucono-delta-lactone, with the use of 1:3 seed-to-water ratio and 70°C or 80°C temperature of addition of coagulant were better in terms of hardness and chewiness.

Keywords

Tofu, kenaf seed, physicochemical quality, seed-to-water, processing variablesIntroduction

For many years, tofu has been considered a popular and important food consumed in East Asia and Southeast Asia [1, 2]. Tofu is also an important source of protein in Africa. It is consumed as a favourite meat substitute in the northern part of Nigeria [3]. Tofu is typically considered a salt or acid-coagulated plant-based gel, with lipids and proteins trapped in the gel networks [4]. It is an inexpensive, nutritious and multipurpose meat substitute with a bland taste and porous texture. It is cholesterol-free, a rich source of proteins, minerals and polyunsaturated fatty acids [5].

Soybean is often used for tofu production. Its preparation generally includes soaking and grinding soybeans in water, filtering, boiling and coagulation of soymilk extract, pressing and moulding. The yield, moisture content, texture and colour profile of tofu are important to product quality and acceptability [2]. Tofu producers and consumers were concerned about textural qualities of the final product and equally the economic prospect of the yield. Several factors could influence the yield and quality of tofu, among which include the type of seeds, coagulant type and concentration, soaking condition of seed, seed-to-water ratio, degree of stirring and stirring time [6, 7]. The seed-to-water ratio which directly determines the amount of water used for grinding and extraction of plant milky extract is also significant because, it affects milky extract solid content, protein recovery and tofu texture. The textural quality characteristics are governed by milky extract concentration, coagulant type and concentration, pressing force and time [5]. MgCl2 and aluminium potassium salt (Potash) have been studied as ionic coagulants for tofu production, while glucono-delta-lactone (GDL) and CH3COOH as an acidic coagulants to produce homogeneous network called tofu [8–10].

Some plant seeds have been used as an alternative to soybean for tofu production, such as peanut [11], lupin seed [12] and sesame[13]. Kenaf seed also has the potential to be used for tofu production. Kenaf seed has more than 20% of protein and protein has been considered as a major component that determines the physicochemical quality of tofu [14, 15]. Similarly, this study attempts to value-add kenaf seed as one of the main ingredients in tofu production. One of the authors has studied the effects of different types of coagulants on the quality characteristics of kenaf seed tofu [16]. However, the holistic effects of coagulants and other processing variables have not been studied. Thus, the objectives of this study were to determine the effects of coagulant types, concentrations and processing conditions (kenaf seed-to-water ratio and temperature of addition of coagulant) on the physical, texture and chemical properties of kenaf seed tofu.

Materials and methods

Materials

The kenaf seed cultivar KB6 was used for the tofu production. The seed was obtained from the National Kenaf and Tobacco Board Perlis, Malaysia. The seed was sorted out and thoroughly washed under running water prior to soaking for onward use in tofu preparation.

Chemicals and reagents

Food grade MgCl2 (analytical research (AR) grade; 99.5% purity), CH3COOH (AR; 99.8%), Potash (AR; ≥ 98% purity), GDL (AR; ≥ 99% purity) were used in this study for coagulation of kenaf seed extract for kenaf seed tofu preparation. All the other chemicals used were of analytical grade.

Experimental design

Randomised full factorial design was used to evaluate the physical, texture and chemical properties of kenaf seed tofu as influenced by four independent factors presented in Table S1, which includes coagulant types (four levels: MgCl2, Potash, GDL and CH3COOH), coagulant concentrations (four levels: 0.25 g/100 mL, 0.50 g/100 mL, 0.75 g/100 mL and 1.00 g/100 mL), seed-to-water ratio (two levels: 1:3 and 1:6) and temperature of addition of coagulant (two levels: 70°C and 80°C). The dependent variables monitored were yield, pH, moisture content, crude protein, crude fat, colour parameters [lightness (L), redness (a*) and yellowness (b*) values] and texture profile analysis (hardness, chewiness, springiness and cohesiveness) of the kenaf seed tofu.

Kenaf seed tofu preparation

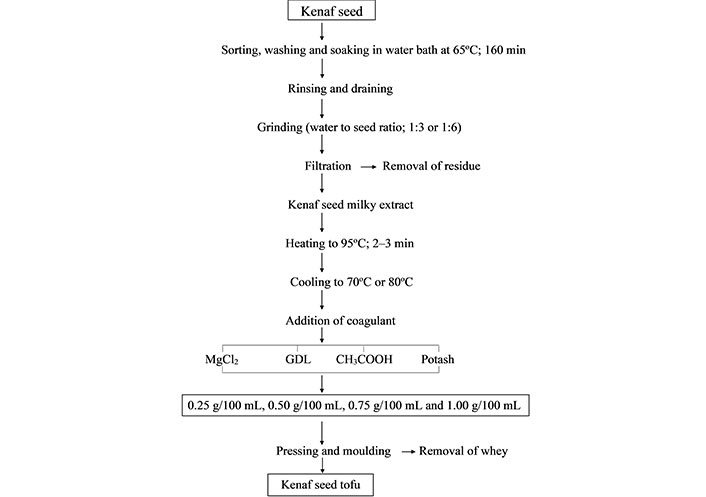

The stepwise processes for kenaf seed tofu preparation were according to the method of Prabhakaran et al. [17] as shown in Figure 1.

Procedure for kenaf seed tofu production. GDL: glucono-delta-lactone; Potash: aluminium potassium salt

Determination of physicochemical properties of kenaf seed tofu

Determination of yield and pH

The yield of the tofu was calculated as the weight of fresh tofu obtained from 100 g of kenaf seed. The pH of the tofu was measured using a bench-top pH meter (Mettler Toledo, FE 20, Japan), 5 g of freshly prepared kenaf seed tofu was homogenised with 20 mL of distilled water and the pH was immediately measured after the pH meter was calibrated with standard buffer solution of pH 4.00, 7.00 and 11.00.

Determination of colour parameters

The L, a* and b* of the kenaf seed tofu were determined using a Chromometer (CR-400 Konica Minolta Inc., Tokyo, Japan) following the method used in the previous study [18]. Briefly, the Chromometer was calibrated using a white ceramic tile. Then, the tofu samples were cut from the centre in a square shape of 5 cm by 5 cm size and scanned using the chromometer.

Determination of chemical composition of kenaf seed tofu

The moisture content of the freshly prepared kenaf seed tofu was determined by the method of Association of Official Analytical Chemists (AOAC) [19]. Briefly, 2 g of fresh kenaf seed tofu was weighed into a pre-weighed crucible (W1), the crucible containing the sample was then weighed as W2 and put into an oven (Gallenkamp, Model OV-160, England) at 105°C for 24 h. After 24 h, the crucible was removed and cooled in a desiccator chamber. Then, the weight of the crucible containing the dried sample was weighed as W3. The percentage moisture content was calculated using the equation below. The crude protein and crude fat contents of the kenaf seed tofu were determined on a dry basis by the AOAC [19]. The tofu samples were dried in an oven at 45°C for 48 h. The dried tofu samples were analysed for crude protein by micro-Kjeldahl and crude fat by the Soxhlet extraction method.

Texture profile analysis of kenaf seed tofu

The texture profile analysis (TPA) of the kenaf seed tofu was determined using heavy-duty texture analyser (Stable Micro System, TA-HD plus 5085, Germany) following the method adopted in the previous study [18]. Following the method, the tofu sample was cut into cubes of 3.0 cm × 3.0 cm × 2.0 cm from the middle position and compressed twice with 70% deformation force using a P36R probe. The texture analyser was pre-set and calibrated before sample analysis. The setting conditions were; pre-test speed 1.0 mm/s, test speed 1.0 mm/s, post-test speed 1.0 mm/s, strain 70%, trigger force 5.0 g and time 5 s. Hardness, springiness, cohesiveness and chewiness were determined for each tofu sample.

Data analysis

Minitab version 17.0 (Lead Technologies, Inc., PA, USA) was used for the design of the experiment and all analyses. The main, 2-way, 3-way and 4-way interactions effects on the dependent variables (responses) were determined based on the P-values and the coefficient of determination (R2) were used to determine the impacts of the independent variables on the responses.

Results

Effect of coagulants and processing factors on the yield and chemical composition of kenaf seed tofu

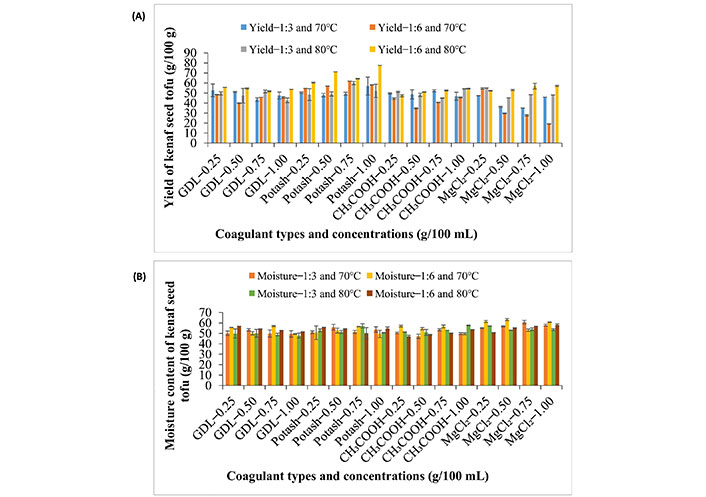

The effects of processing factors (kenaf seed-to-water ratio and temperature of extract at the point of coagulant addition), and coagulant types and concentrations on the yield and moisture content of the kenaf seed tofu are presented in Figure 2. The yield of the different kenaf seed tofu differs significantly with an R2-value of 96.55% (Table 1). All the main factors (kenaf seed-to-water ratio, the temperature of addition of coagulant, coagulant types and concentrations) had significant effects on the yield of the kenaf seed tofu (Table 1). Likewise, all the second-order interactions such as coagulant types*coagulant concentrations, coagulant types*kenaf seed-to-water ratio, coagulant types*temperature of addition of coagulant, coagulant concentrations*temperature of addition of coagulant had significant effects on the yield of the tofu, except coagulant concentrations*kenaf seed-to-water ratio (Table 1). Third-order interactions also had significant effects on the yield of the kenaf seed tofu, except coagulant types*kenaf seed-to-water ratio*temperature of addition of coagulant and the fourth-order interactions had a significant influence on the yield of kenaf seed tofu (Table 1). These implied that interactions among the processing factors had significant effects on the yield of the tofu.

Effects of kenaf seed-to-water ratio, temperature of addition of coagulant, coagulant types and concentrations on the yield and moisture content of kenaf seed tofu. (A) Yield of kenaf seed tofu; (B) moisture content of kenaf seed tofu. GDL: glucono-delta-lactone; Potash: aluminium potassium salt. 1:3 and 1:6: seed-to-water ratio; 70°C and 80°C: temperature of addition of coagulant; GDL–0.25 to GDL–1.00: GDL coagulated tofu with 0.25 g/100 mL, 0.50 g/100 mL, 0.75 g/100 mL and 1.00 g/100 mL; Potash–0.25 to Potash–1.00: Potash coagulated tofu 0.25 g/100 mL, 0.50 g/100 mL, 0.75 g/100 mL and 1.00 g/100 mL; CH3COOH–0.25 to CH3COOH–1.00: CH3COOH coagulated tofu with 0.25 g/100 mL, 0.50 g/100 mL, 0.75 g/100 mL and 1.00 g/100 mL concentration; MgCl2–0.25 to MgCl2–1.00: MgCl2 coagulated tofu with 0.25 g/100 mL, 0.50 g/100 mL, 0.75 g/100 mL and 1.00 g/100 mL

The R2, main and interaction effects of independent factors for kenaf seed tofu production

| Response | R2 (%) | Main effects | 2-Way interactions | 3-Way interactions | 4-Way interactions | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| X1 | X2 | X3 | X4 | X1X2 | X1X3 | X1X4 | X2X3 | X2X4 | X3X4 | X1X2X3 | X1X2X4 | X1X3X4 | X2X3X4 | X1X2X3X4 | ||

| Yield (g/100 g) | 96.550 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 | 0.982 | 0.000 | 0.000 | 0.000 | 0.000 | 0.125 | 0.000 | 0.000 |

| Moisture (g/100 g) | 84.930 | 0.000 | 0.074 | 0.028 | 0.053 | 0.005 | 0.003 | 0.000 | 0.157 | 0.001 | 0.527 | 0.004 | 0.007 | 0.000 | 0.002 | 0.000 |

| pH | 99.000 | 0.000 | 0.000 | 0.000 | 0.258 | 0.000 | 0.000 | 0.000 | 0.005 | 0.225 | 0.007 | 0.000 | 0.000 | 0.000 | 0.000 | 0.000 |

| Crude protein (g/100 g) | 87.260 | 0.000 | 0.408 | 0.000 | 0.000 | 0.001 | 0.000 | 0.067 | 0.006 | 0.000 | 0.000 | 0.009 | 0.000 | 0.028 | 0.638 | 0.001 |

| Crude fat (g/100 g) | 70.500 | 0.016 | 0.542 | 0.000 | 0.000 | 0.145 | 0.001 | 0.041 | 0.354 | 0.559 | 0.466 | 0.707 | 0.434 | 0.004 | 0.174 | 0.187 |

| L | 76.690 | 0.000 | 0.104 | 0.006 | 0.000 | 0.110 | 0.002 | 0.001 | 0.487 | 0.970 | 0.003 | 0.815 | 0.045 | 0.000 | 0.086 | 0.162 |

| a* | 79.970 | 0.000 | 0.272 | 0.954 | 0.781 | 0.103 | 0.003 | 0.000 | 0.084 | 0.778 | 0.081 | 0.499 | 0.014 | 0.022 | 0.257 | 0.000 |

| b* | 92.300 | 0.000 | 0.484 | 0.000 | 0.000 | 0.070 | 0.000 | 0.000 | 0.112 | 0.258 | 0.000 | 0.000 | 0.000 | 0.000 | 0.017 | 0.000 |

| Hardness (g) | 74.270 | 0.000 | 0.007 | 0.884 | 0.578 | 0.037 | 0.001 | 0.465 | 0.493 | 0.116 | 0.744 | 0.555 | 0.040 | 0.177 | 0.625 | 0.222 |

| Chewiness | 61.880 | 0.017 | 0.041 | 0.359 | 0.943 | 0.181 | 0.001 | 0.287 | 0.293 | 0.323 | 0.954 | 0.087 | 0.121 | 0.680 | 0.545 | 0.676 |

| Springiness (mm) | 65.160 | 0.013 | 0.477 | 0.940 | 0.326 | 0.461 | 0.005 | 0.527 | 0.685 | 0.189 | 0.702 | 0.026 | 0.019 | 0.021 | 0.342 | 0.086 |

| Cohesiveness | 74.560 | 0.000 | 0.045 | 0.002 | 0.016 | 0.279 | 0.003 | 0.003 | 0.355 | 0.010 | 0.534 | 0.002 | 0.103 | 0.147 | 0.178 | 0.165 |

X1: coagulant types; X2: coagulant concentrations; X3: ratio of kenaf seed-to-water; X4: temperature of coagulant addition

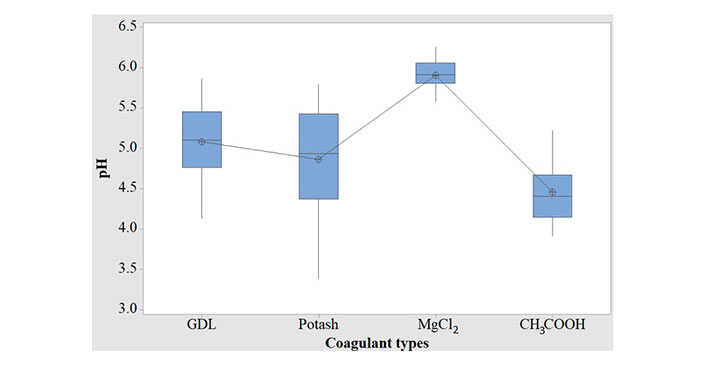

The R2-value (99.00%) for the pH, indicated that changes observed in the pH of the tofu were due to the independent variables. The main factors and the interaction factors significantly affected the pH of the tofu, except for the main effect of temperature of addition of coagulant and second-order interaction effect of coagulant concentrations*temperature of addition of coagulant. The pH (5.91) of the kenaf seed tofu made with MgCl2 was significantly higher, followed by GDL (5.08) and potash (4.86) coagulated tofu, and CH3COOH coagulated tofu had the lowest pH of 4.46 Figure 3.

The moisture content for the kenaf seed tofu differs significantly. The main factors, second, third and fourth order interactions had significant effects on the moisture content of the tofu, except for coagulant concentrations, temperature of addition of coagulant, coagulant concentrations*kenaf seed-to-water ratio, and kenaf seed-to-water ratio*temperature of addition of coagulant (Table 1).

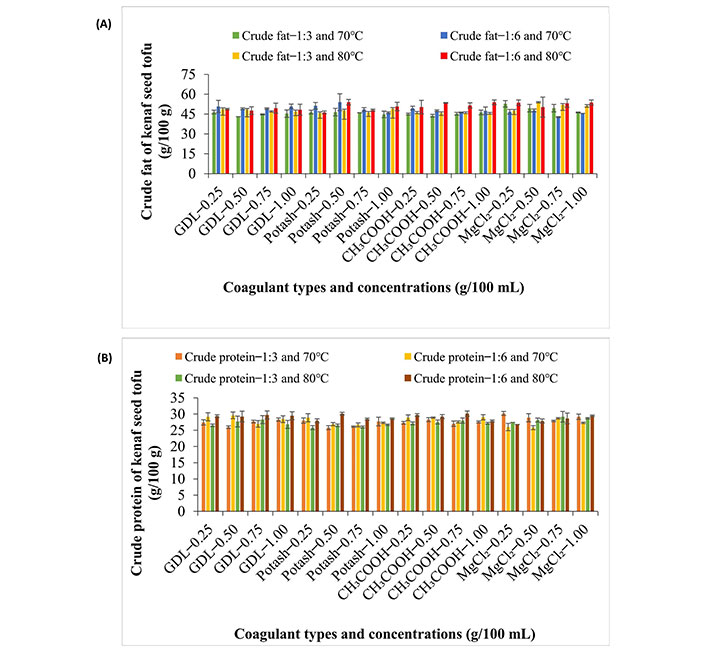

The effects of kenaf seed-to-water ratio, temperature of addition of coagulant, coagulant types and concentrations on the crude fat and crude protein contents of the kenaf seed tofu are presented in Figure 4. The crude fat of the tofu ranges from 43.00 g/100 g to 54.00 g/100 g (Figure 4A). While the crude protein ranges from 25.96 g/100 g to 30.19 g/100 g (Figure 4B).

Effects of kenaf seed-to-water ratio, temperature of addition of coagulant, coagulant types and concentrations on the crude fat and protein content of kenaf seed tofu. (A) Crude fat of kenaf seed tofu; (B) crude protein of kenaf seed tofu. GDL: glucono-delta-lactone; Potash: aluminium potassium salt

The type of added coagulant, seed-to-water ratio and the temperature of addition of coagulant had significant effects on the crude fat and crude protein of the kenaf seed tofu (Table 2). Likewise, second-order interactions of the above-mentioned factors had a significant influence on the crude fat and crude protein content of the tofu, except for the coagulant type*temperature of addition of coagulant which did not significantly affect the crude protein of the tofu. In addition, the third and fourth orders interactions did not have significant effects on the crude fat of the kenaf seed tofu, except for coagulant types*seed-to-water ratio*temperature of addition of coagulant (Table 1). Contrary to that of the crude fat, in the case of the crude protein the third-order and fourth-order interactions significantly affected the crude protein of the kenaf seed tofu, except for the third-order interaction of coagulant concentrations*seed-to-water ratio*temperature of addition of coagulant.

Pearson correlation coefficient (r) and P-value of relationship among the TPA of kenaf seed tofu as affected by coagulants and processing factors

| TPA | Hardness (g) | Chewiness | Cohesiveness | Springiness (mm) | ||||

|---|---|---|---|---|---|---|---|---|

| P-value | r-value | P-value | r-value | P-value | r-value | P-value | r-value | |

| Hardness (g) | - | - | 0.000 | +0.649 | +0.892 | –0.012 | +0.201 | +0.114 |

| Chewiness | 0.000 | +0.649 | - | - | 0.000 | +0.544 | 0.000 | +0.553 |

| Cohesiveness | +0.892 | –0.012 | 0.000 | +0.544 | - | - | 0.000 | +0.625 |

| Springiness (mm) | +0.201 | +0.114 | 0.000 | +0.553 | 0.000 | +0.625 | - | - |

TPA: texture profile analysis; -: the same response, no relationship; +: positive relationship; –: negative relationship

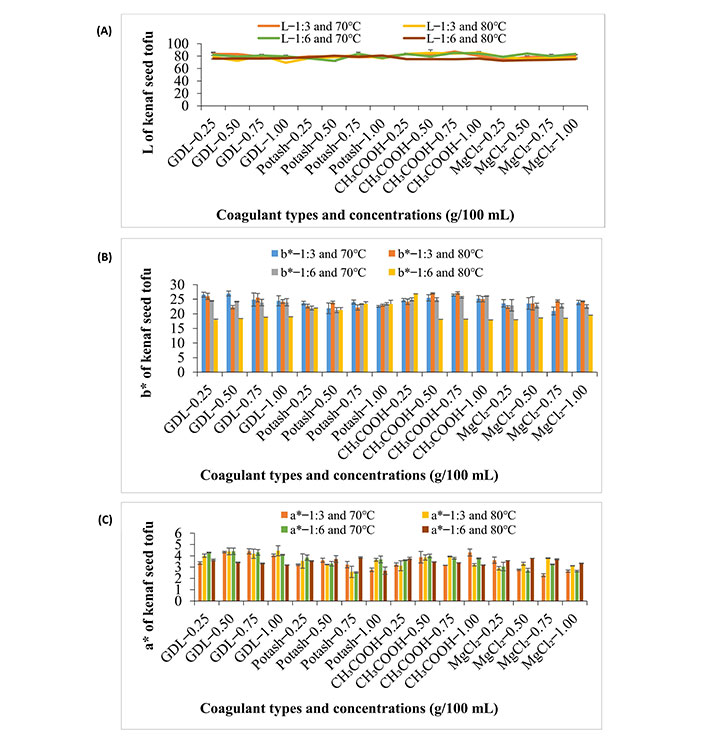

Effect of coagulants and processing variables on the colour parameters of kenaf seed tofu

The effects of kenaf seed-to-water ratio, temperature of addition of coagulant, coagulant types and concentrations on the colour properties of kenaf seed tofu is presented in Figure 5. The results indicated significant interactions among factors on the L, b* and a*, except coagulant concentrations and interactions involving coagulant concentrations (Table 1).

Effects of kenaf seed-to-water ratio, temperature of addition of coagulant, coagulant types and concentrations on the colour profile of kenaf seed tofu. (A) L of kenaf seed tofu; (B) b* of kenaf seed tofu; (C) a* of kenaf seed tofu. GDL: glucono-delta-lactone; Potash: aluminium potassium salt; L: lightness; b*: yellowness; a*: redness

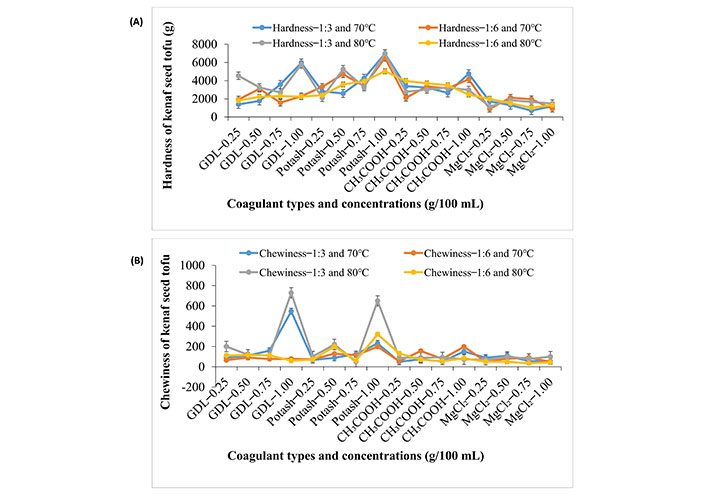

Effect of coagulants and processing variables on the TPA of kenaf seed tofu

The main factors (linear model) had significant effects on the hardness of the kenaf seed tofu, except kenaf seed-to-water ratio and temperature of addition of coagulant (Table 1). The second, third and fourth orders interactions were not significant, except for interaction between coagulant types*kenaf seed-to-water ratio (Table 1). This implied that as the amount of water used for the extraction of the kenaf seed milky extract increased, the total soluble component of the extract would become more diluted, and more coagulant concentration would be needed. These will subsequently lead to the formation of a less-harder tofu. As shown in Figure 6A, GDL and Potash coagulated tofu with a 1:3 kenaf seed-to-water ratio, temperature of addition of coagulant at 70°C and 80°C produced tofu with the highest hardness.

Effects of kenaf seed-to-water ratio, temperature of addition of coagulant, coagulant types and concentrations on the texture profile of kenaf seed tofu. (A) Hardness of kenaf seed tofu; (B) chewiness of kenaf seed tofu. GDL: glucono-delta-lactone; Potash: aluminium potassium salt

The chewiness of the tofu also follows the same pattern as that of the hardness characteristic. The degree of chewiness increased as the coagulant concentration was increased for the four types of coagulant. GDL and Potash, at 1:3, temperature of addition of coagulant at 80°C had the highest chewiness (Figure 6B). A significant, strong positive relationship between the kenaf seed tofu hardness and chewiness was observed (Table 2), indicating an increase in the kenaf seed tofu hardness leading to an increase in the chewiness of the tofu.

The springiness of the kenaf seed tofu was affected by the main factor of coagulant types, second-order interaction effect of coagulant types*seed-to-water ratio and third-order interactions effects (Table 1). The R2-value of the model was found to be 65.16% and this value indicated that 65.16% changes in the springiness of the kenaf seed tofu were due to the independent variables. The cohesiveness of the kenaf seed tofu was affected by the main factors of coagulant types, seed-to-water ratio, and temperature of addition of coagulant, in addition to the second-order interaction effects (coagulant types*seed-to-water ratio, coagulant types*temperature of addition of coagulant, and coagulant concentrations*temperature of addition of coagulant) and the third-order interaction effect (coagulant types*coagulant concentrations*seed-to-water ratio) all affected the cohesiveness of the kenaf seed tofu (Table 1). The relationship between the cohesiveness and springiness of the kenaf seed tofu was significant and moderate positive correlation (Table 2). This finding implied that an increase in the internal force of the kenaf seed tofu leads to a corresponding increase in the ability of the tofu to return to its original state after undergoing mechanical stress. Additionally, the correlation between the kenaf seed tofu cohesiveness and chewiness, springiness and chewiness were significant with a moderate positive relationship (Table 2). However, the relationship between the kenaf seed tofu cohesiveness and hardness, springiness and hardness were not significant with negative and positive weak correlations, respectively (Table 2).

Discussion

The high R2-value of the yield of tofu showed that 96.55% variations in the yield of kenaf seed tofu were explained by the independent factors. The kenaf seed tofu produced with 0.50 g/100 mL and 1.00 g/100 mL of Potash at 1:6 seed-to-water ratio and 80°C temperature of addition of coagulant formed tofu with the highest yield of 71.22 g/100 g and 77.57 g/100 g, respectively (Figure 2A), these increased in the yield of the tofu were due to the increased in the total volume of the kenaf seed milky extract used for the tofu production as 1:6 ratio will give higher volume of the milky extract than 1:3 ratio. Shih et al. [5] reported that the yield of soybean tofu decreased as the volume of the soybean milky extract used for the tofu production decreased. The average yield of the tofu based on the type of coagulant increased as the coagulant type changed from CH3COOH (47.82 g/100 g) to GDL (48.98 g/100 g) and Potash (57.41 g/100 g) then decreased with MgCl2 (44.47 g/100 g). Physical observation indicated that heating of kenaf seed milky extract to 95°C and holding it for about 2 min to 3 min initiated the formation of a curd and the addition of coagulant after cooling to 80°C or 70°C further enhanced the curd formation. But, heating below 80°C coupled with the addition of coagulant caused a distortion of curd leading to a loss of coagulating capability. This is because, the denaturation of the kenaf seed protein began to occur at 80°C, since the onset of denaturation of the kenaf seed protein determined using differential scanning calorimeter was found to be around 99°C (unpublished), heating the kenaf milky extract to 95°C, facilitated the denaturation process and caused the protein to aggregate together.

The R2-value for the moisture content of the kenaf seed tofu (Table 1), indicates that 84.93% of changes in the value of the moisture content of the tofu were due to the model or independent factors. The moisture content for the kenaf seed tofu ranges from 47.09 g/100 g to 63.30 g/100 g (Figure 2B). These values were lower than the range of moisture content reported for soybean tofu 70.6 g/100 g to 82.6 g/100 g [3, 20] and 78.07 g/100 g to 88.48 g/100 g for peanut tofu [11]. The variation in the moisture content of the kenaf seed tofu to that of soybean tofu might be because of differences in the water-holding capacity of the kenaf seed and soybean tofu.

The range of values obtained for the crude fat of the kenaf seed tofu were higher than the values of 12.30 g/100 g to 13.70 g/100 g for soybean tofu made with different organic acids such as Epsom salt, lemon juice, alum and top water of fermented maize [3]. The author also found higher values for the crude protein content of the soybean tofu (54.20 g/100 g to 58.20 g/100 g).

The L-value varies for the different formulated tofu and it ranges from 69.58 to 85.57 (Figure 5A). This range of values is similar to the L of soybean tofu reported by Obatolu [3]. While the b*-value of the tofu ranges from 17.88 to 27.16 (Figure 5B). The b*-values fell within the values of b* of soybean tofu [3, 17]. The a* of the kenaf seed tofu varies from 2.29 to 4.45 (Figure 5C). This range of values was significantly higher than the a* of soybean tofu produced under different conditions [3, 17]. This is contrary to the cultivar of soybean used for soybean tofu production by Khatib et al. [21], which had higher a*-values (3.27 to 4.39) similar to the a*-values of the kenaf seed tofu. Variations in the distribution of pigments in the hilum of seeds can significantly alter the colour profile of the final products. Kenaf seed tofu is more reddish in colour compared to soybean tofu. The ranking order of the colour parameters for the kenaf tofu is L > b* > a*. Moreover, the favourite colour for tofu is white or creamy white [22]. Although the a* of kenaf seed tofu was higher than that of soybean tofu, the dominancy of the b* and L colour over the a* make kenaf seed tofu appears to have a creamy-like colour similar to that of soybean tofu.

Analysis of texture is a vital procedure to understand the quality of tofu. The hardness of the tofu increased as the concentration of the coagulant increased for the different formulations. The coagulant concentration (1.00 g/100 mL) produced the stiffest tofu (Figure 6A). Contrary to the findings of Cao et al. [4] who reported a decrease in the hardness of soybean tofu at higher concentrations of organic acids. Tofu made with a 1:3 seed-to-water ratio*temperature of addition of coagulant at 80°C also produced tofu with a significantly harder texture (Figure 6A).

In conclusion, coagulants and processing factors significantly affected the physicochemical and textural properties of the kenaf seed tofu. Potash was found to produce tofu with the highest yield, chewiness and hardness followed by GDL and MgCl2 produces tofu with the lowest yield and less hardness. All the kenaf seed tofu produced in this study had a creamy-like colour. The tofu made from milky extract obtained by grinding seed-to-water ratio of 1:3 and by adding coagulant to the milky extract at 70°C or 80°C was better in terms of hardness and chewiness.

Abbreviations

| a*: | redness |

| AR: | analytical research |

| b*: | yellowness |

| GDL: | glucono-delta-lactone |

| L: | lightness |

| Potash: | aluminium potassium salt |

| R2: | coefficient of determination |

| TPA: | texture profile analysis |

Supplementary materials

The supplementary material for this article is available at: https://www.explorationpub.com/uploads/Article/file/101035_sup_1.pdf

Declarations

Author contributions

SGI: Investigation, Writing—original draft, Visualization, Methodology, Data curation. RK: Supervision, Conceptualization, Funding acquisition, Project administration, Resources.

Conflicts of interest

The authors declare that they have no conflicts of interest.

Ethical approval

Not applicable.

Consent to participate

Not applicable.

Consent to publication

Not applicable.

Availability of data and materials

Data from this manuscript will be made available upon reasonable request. Email: shafaatu.ibrahim@udusok.edu.ng

Funding

This study was financially supported by the National Kenaf and Tobacco Board (LKTN) of Malaysia [UPM Vot No.: 6300910]; the Tertiary Education Trust Fund, Nigeria (TETfund) and Usmanu Danfodiyo University, Sokoto-Nigeria (UDUs). The funders had no role in the study design, data collection and analysis, decision to publish, or preparation of the manuscript.

Copyright

© The Author(s) 2024.