7 results in Exploration of Musculoskeletal Diseases

Latest

Sort by :

- Latest

- Most Viewed

- Most Downloaded

- Most Cited

Open Access

Original Article

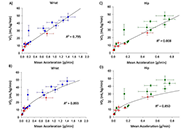

Nonlinear modification to Hildebrand equation for accelerometry assessment of physical activity: improved accuracy for low activity levels

Laura A. Frey-Law ... Kathleen A. Sluka

Published: September 13, 2024 Explor Musculoskeletal Dis. 2024;2:408–422

Open Access

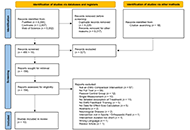

Systematic Review

Role and effectiveness of surface EMG feedback in sports and orthopedic rehabilitation: a systematic review

Thomas Haab ... Paul Burkey

Published: September 12, 2024 Explor Musculoskeletal Dis. 2024;2:391–407

Open Access

Original Article

Successful implementation of interchange of biologic medications in chronic arthritis after information of costs to prescribers

Fernando Perez-Ruiz ... Amaya de Basagoiti-Gorordo

Published: September 10, 2024 Explor Musculoskeletal Dis. 2024;2:384–390

This article belongs to the special issue Biosimilars: State of the Art in the Treatment of Rheumatic Diseases

Open Access

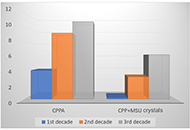

Original Article

Prevalence and factors associated to calcium pyrophosphate arthritis in patients with gout

Fernando Perez-Ruiz ... Frédéric Lioté

Published: September 10, 2024 Explor Musculoskeletal Dis. 2024;2:375–383

This article belongs to the special issue Calcium Pyrophosphate Deposition Disease

Open Access

Review

Safety and efficacy of gout treatments in people with renal impairment

Hamish Farquhar ... Lisa K. Stamp

Published: September 02, 2024 Explor Musculoskeletal Dis. 2024;2:360–374

This article belongs to the special issue Pharmacological and Non-Pharmacological Management of Gout

Open Access

Original Article

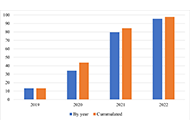

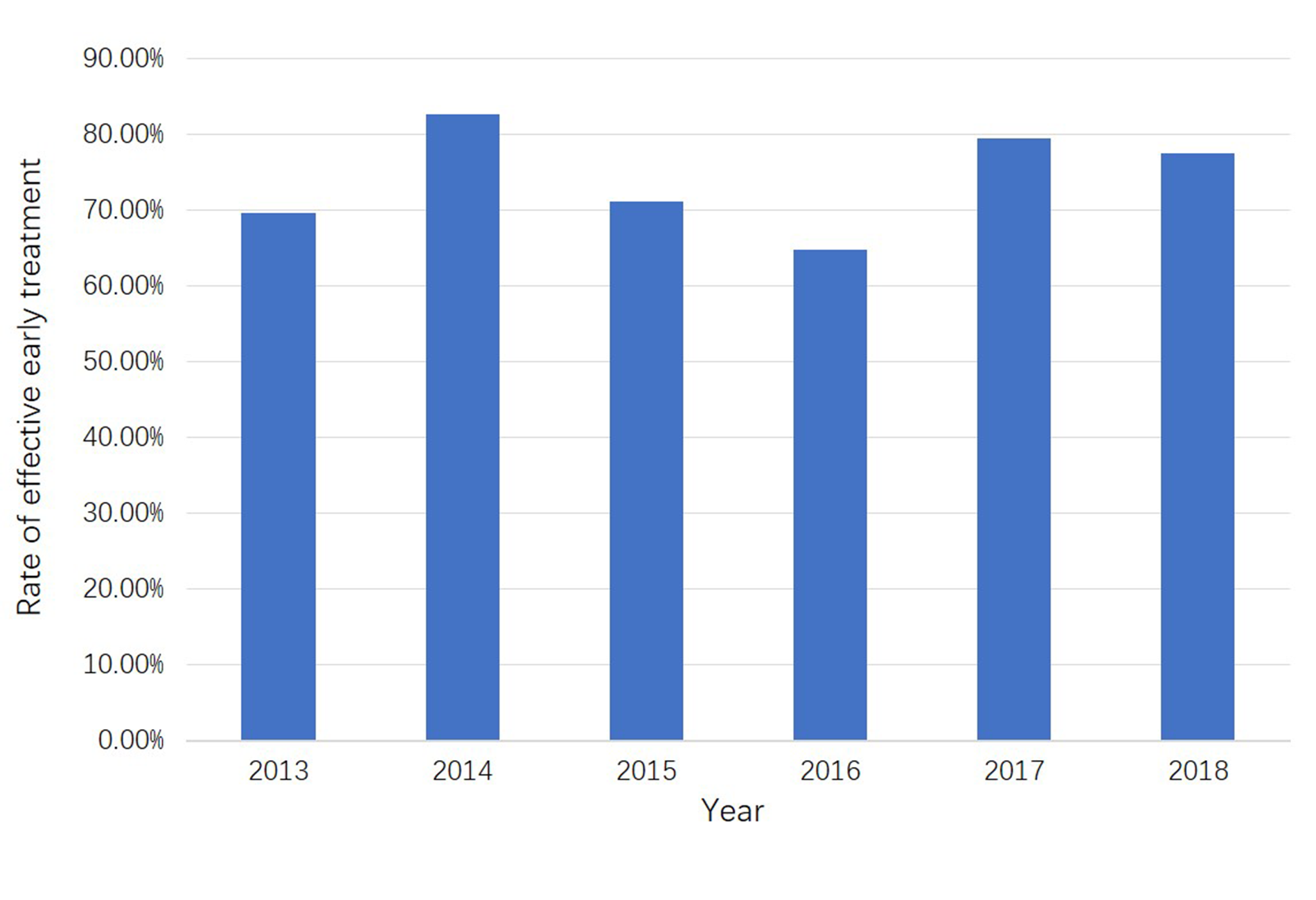

Experience in the application of the Graf technique in Beijing

Jingnan He ... Xuemin Lyu

Published: July 31, 2024 Explor Musculoskeletal Dis. 2024;2:353–359

This article belongs to the special issue Baby Hip Sonography Worldwide: Experience, Results, and Recommendations

Open Access

Case Report

Ergonomic evaluation of assembly line work activity in the automotive industry: a case study

Raquel Ferreira Araruna de Carvalho, Márcio Alves Marçal

Published: July 30, 2024 Explor Musculoskeletal Dis. 2024;2:336–352

This article belongs to the special issue Prevalence and Risk Factors of Work-related Musculoskeletal Disorders

Journal Information

Previous

Previous